Interoperability Test System for EPC

Compliant Class-1 Generation-2 UHF

RFID Devices

INTEROPERABILITY TEST METHODOLOGY

Version 1.2.4

Date: 2006-06-27 Version 1.2 Page 1 of 84

Interoperability Test System for EPC compliant Class-1 Gen-2 UHF RFID

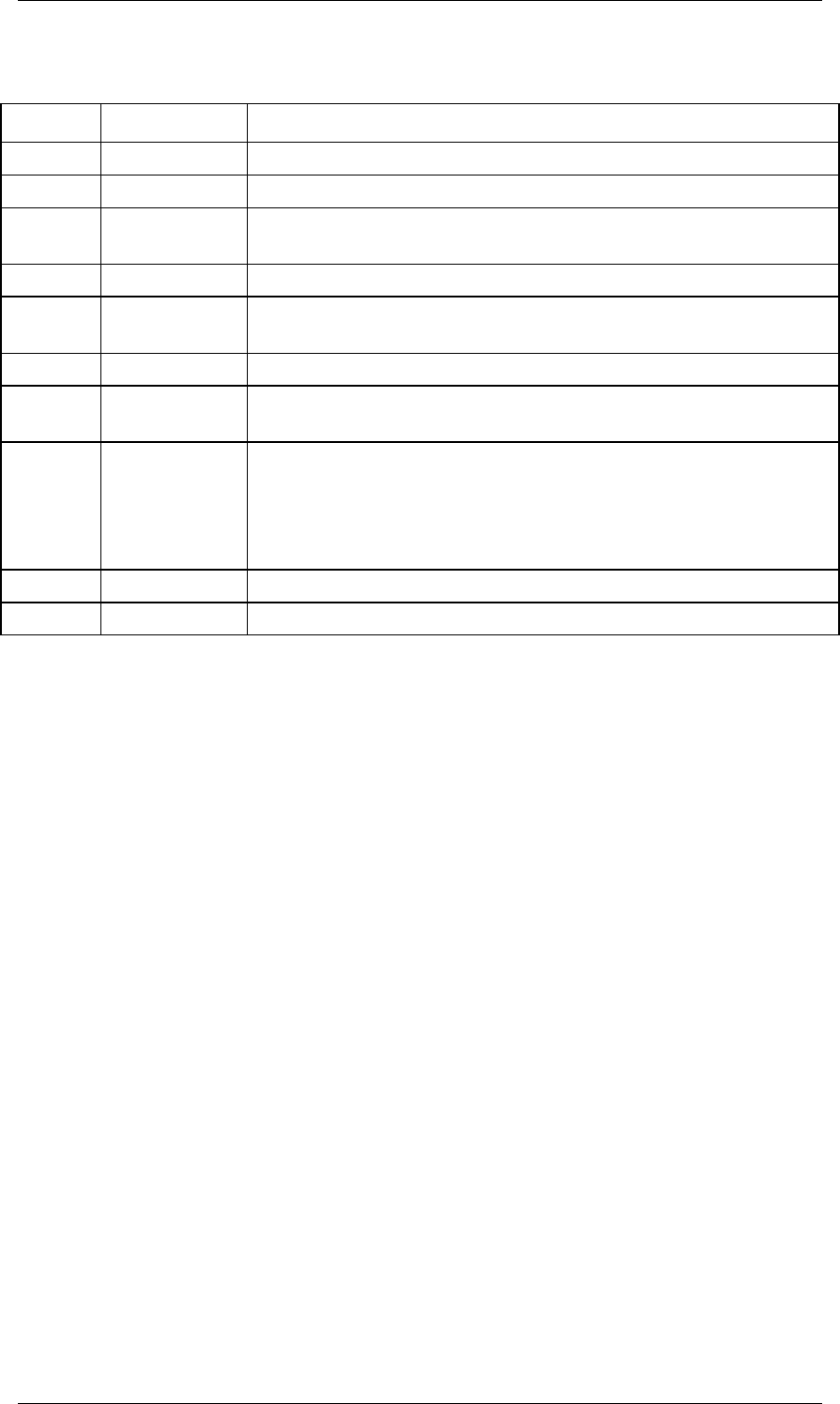

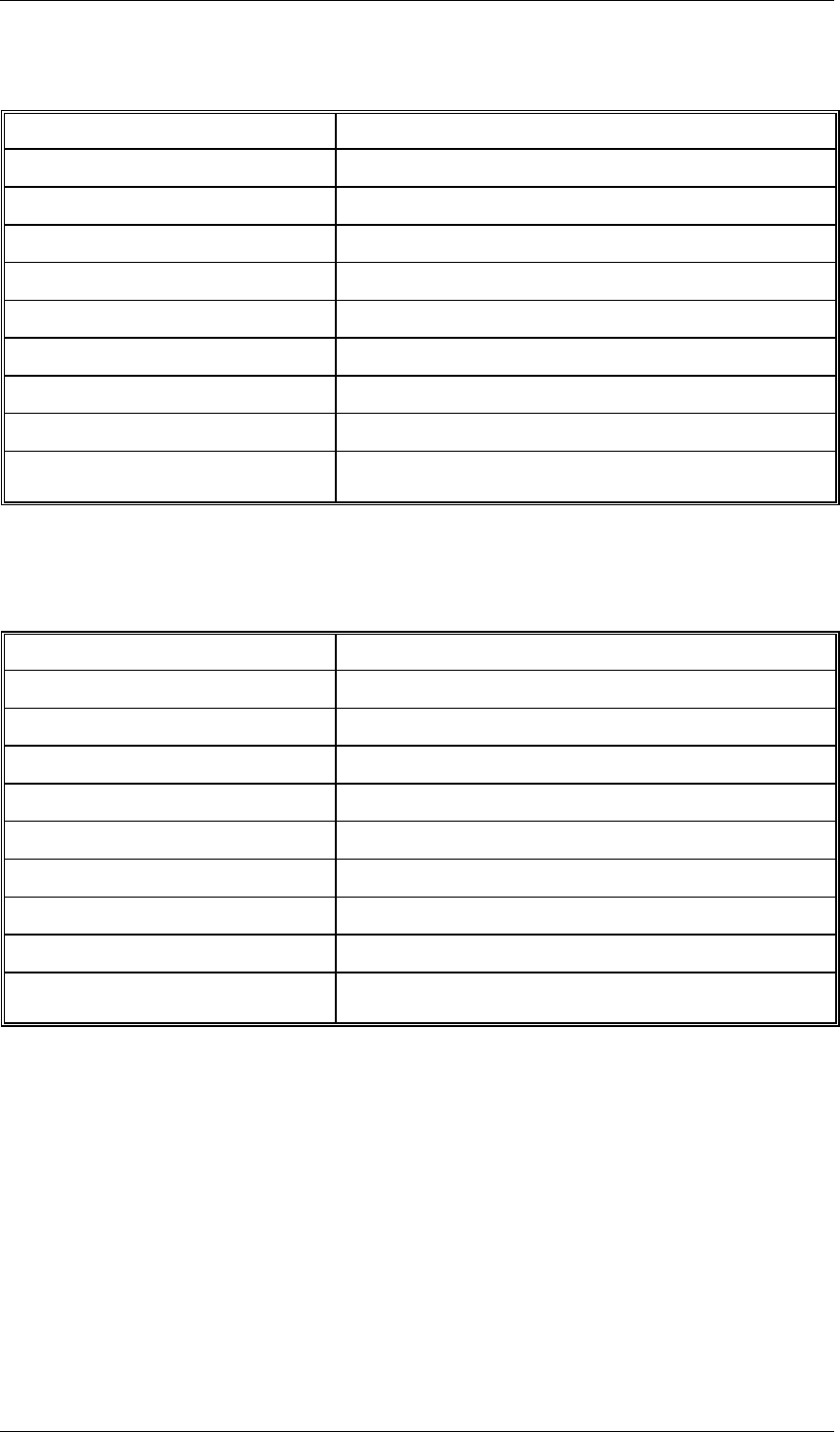

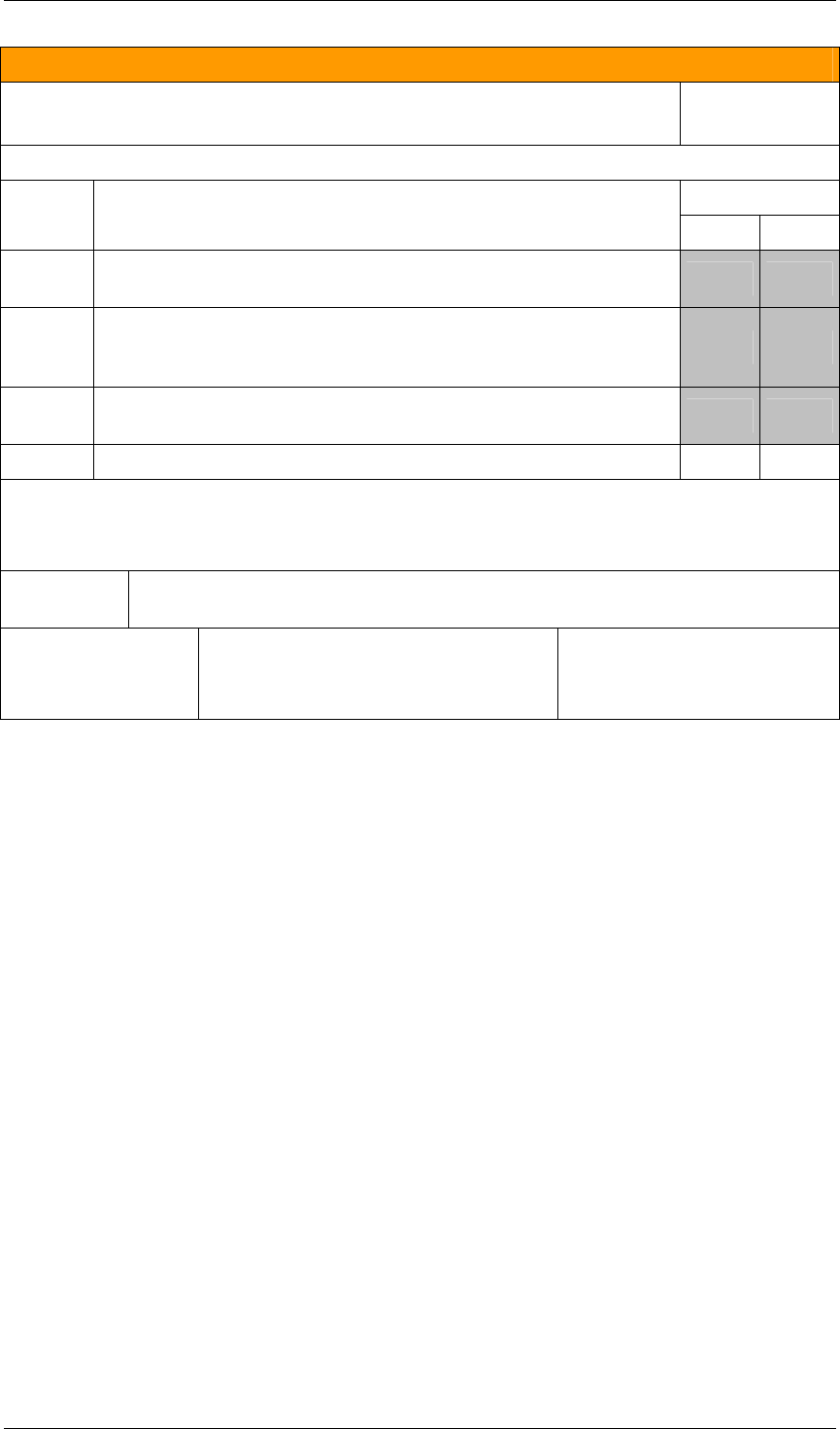

Revision History

Revision Date Comments

0.1 2004-11-15 First release

2.0 2005-03-17 Major changes

3.0 2006-05-29 Replaced sections 6 and 7, revising list of test cases and introducing

scripting requirements as a means for rapid and thorough testing

3.1 2006-06-02 Merged all annexes and added printer requirements

1.0 2006–06-09 Restarted Revision Number - Removed CETECOM Logo Rearranged

some sections

1.1 2006-06-15 Revised Document for Editorial and Structural Changes

1.2 2006-06-27 Updated section 6, clarifying and reorganizing test cases with some

modifications made to the scripting syntax

1.2.2 2006-07-26 Put further clarification into the Lock/PermLock command set.

Replaced PU_AP_L_1 and PU_AP_L_2 with PL_ AP_L_1 and

PL_AP_L_2 because these commands were taken care of by other

test cases. Added PU_E_PU, PU_T_PU and PU_U_PU to test these

failing cases. Corrected SQ_E_S3_8 pointer. Updated SQ command.

1.2.3 2006-08-03 Revised Select/Query Test Cases table for pointer and length specs.

1.2.4 2006-08-04 Revised for editorial change to Select/Query Test Cases table.

Contributors

Rosario Trapero, CETECOM, Spain

Mª José Rodríguez CETECOM, Spain

Vince Moretti Impinj, USA

Hoosamuddin Bandukwala MET Laboratories, USA

Gaylon D. Morris MET Laboratories, USA

Disclaimer and copyright notice

THIS DRAFT DOCUMENT IS PROVIDED “AS IS” WITH NO WARRANTIES

WHATSOEVER, INCLUDING ANY WARRANTY OF MERCHANTABILITY,

NONINFRINGEMENT, FITNESS FOR ANY PARTICULAR PURPOSE, OR ANY

WARRANTY OTHERWISE ARISING OUT OF ANY PROPOSAL, SPECIFICATION OR

SAMPLE. Any liability, including liability for infringement of any proprietary rights, relating to

use of information in this document is disclaimed.

No license, express or implied, by estoppels or otherwise, to any intellectual property rights are

granted herein.

Date: 2006-08-04 Version 1.2.4 Page 2 of 84

Interoperability Test System for EPC compliant Class-1 Gen-2 UHF RFID

Date: 2006-08-04 Version 1.2.4 Page 3 of 84

Interoperability Test System for EPC compliant Class-1 Gen-2 UHF RFID

Table of Contents

1.0 Scope...................................................................................................................................7

2.0 References ..........................................................................................................................7

3.0 Definitions and Abbreviations..........................................................................................8

3.1 Definitions ..............................................................................................................8

3.2 Abbreviations.........................................................................................................9

4.0 Procedures........................................................................................................................10

4.1 Procedures............................................................................................................10

5.0 Test Suite Design..............................................................................................................11

5.1 Test Suite Overview.............................................................................................11

5.2 Test Cases.............................................................................................................12

6.0 Scripting Language .........................................................................................................21

6.1 Script Language Syntax......................................................................................21

6.2 Script File Example.............................................................................................31

6.3 Output File Example...........................................................................................31

7.0 Test Sites...........................................................................................................................34

7.1 General Characteristics ......................................................................................34

7.2 Multiple-tag Setup...............................................................................................34

7.3 Test Sites for Interoperability ............................................................................35

7.4 Qualified Equipment...........................................................................................37

7.5 Test System Validation........................................................................................37

A.1 Scope................................................................................................................................38

A.2 References .......................................................................................................................38

A.3 Definitions .......................................................................................................................38

A.4 Abbreviations..................................................................................................................38

A.5 Conformance to this IS proforma specification...........................................................38

A.6 Guidance for completing the IS proforma....................................................................39

A.6.1 Purposes and structure .......................................................................................39

A.6.2 Abbreviations and conventions ..........................................................................39

A.6.3 Instructions for completing the IS proforma....................................................40

A.6.4 Identification of the implementation .................................................................40

A.6.5. Roles.....................................................................................................................42

A.7 Operating Parameters.....................................................................................................48

B.1 Test Laboratory...............................................................................................................50

B.2 Client.................................................................................................................................51

B.3 Manufacturer...................................................................................................................51

B.4 Implementation Under Test............................................................................................52

B.5 Implementation Under Test 2.........................................................................................52

B.6 Testing Environment.......................................................................................................53

B.7 Means of testing identification:......................................................................................53

B.8 Test conditions:................................................................................................................53

B.9 Limits and reservations...................................................................................................54

B.10 Record of agreement .......................................................................................................54

B.11 Iut Conformance Status..................................................................................................55

B.12 Static Conformance Summary.......................................................................................55

B.13 Dynamic Conformance Summary..................................................................................55

B.14 Static Conformance Review Report...............................................................................55

B.15 Test Campaign Report....................................................................................................56

Date: 2006-08-04 Version 1.2.4 Page 4 of 84

Interoperability Test System for EPC compliant Class-1 Gen-2 UHF RFID

B.16 Observations ....................................................................................................................56

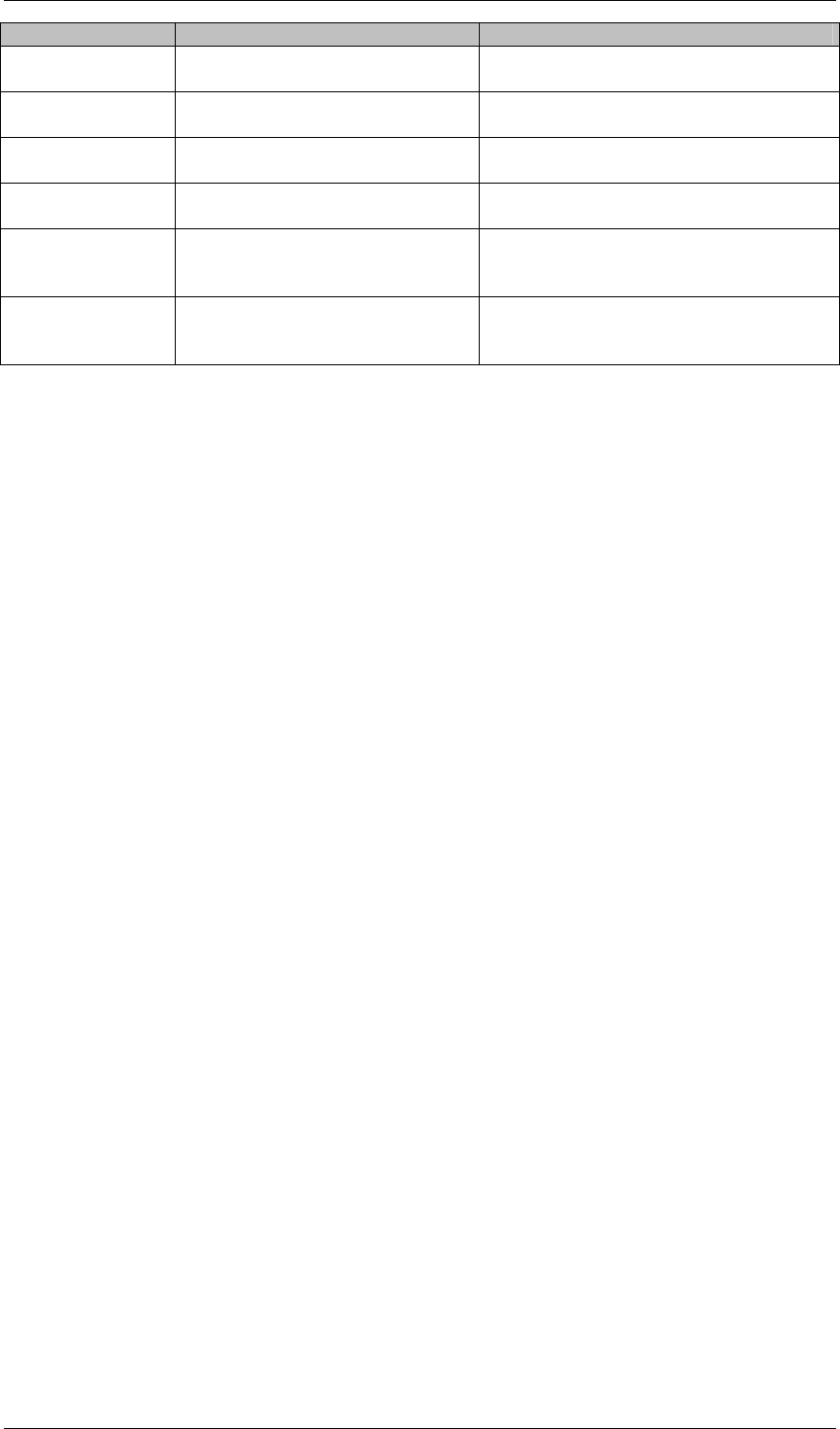

C.1 Manufacturer Data..........................................................................................................57

C.2 Manufacturer Identification...........................................................................................58

C.3 Reference from EPCglobal Gen 2 Specification...........................................................59

C.4 Test Suit Structure ..........................................................................................................60

C.5 TP Naming Convention...................................................................................................62

C.6 Test Case Procedures ......................................................................................................63

D.1 Qualified Equipment.......................................................................................................71

D.2 Definitions of Interoperability Testing Terms:.............................................................72

D.3 Selection of QE.................................................................................................................73

D.4 Evaluation of the products..............................................................................................73

D.5 Test Equipment................................................................................................................74

D.6 Test Equipment................................................................................................................77

D.7 Hardware Description.....................................................................................................78

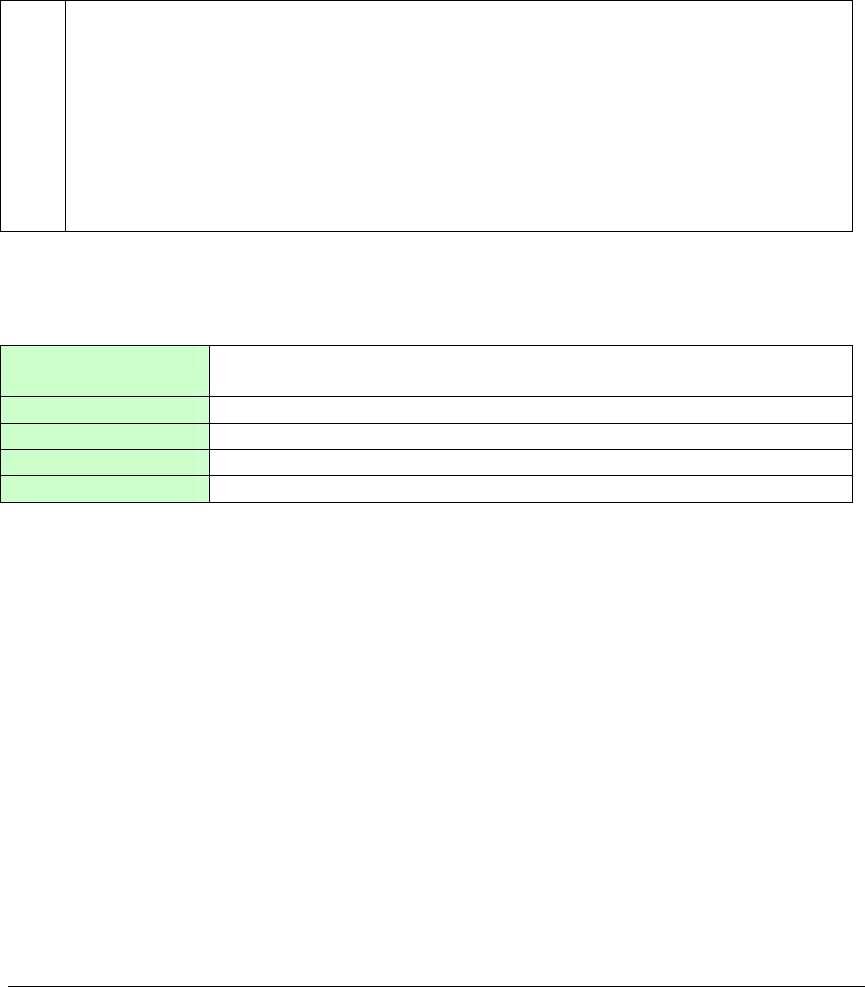

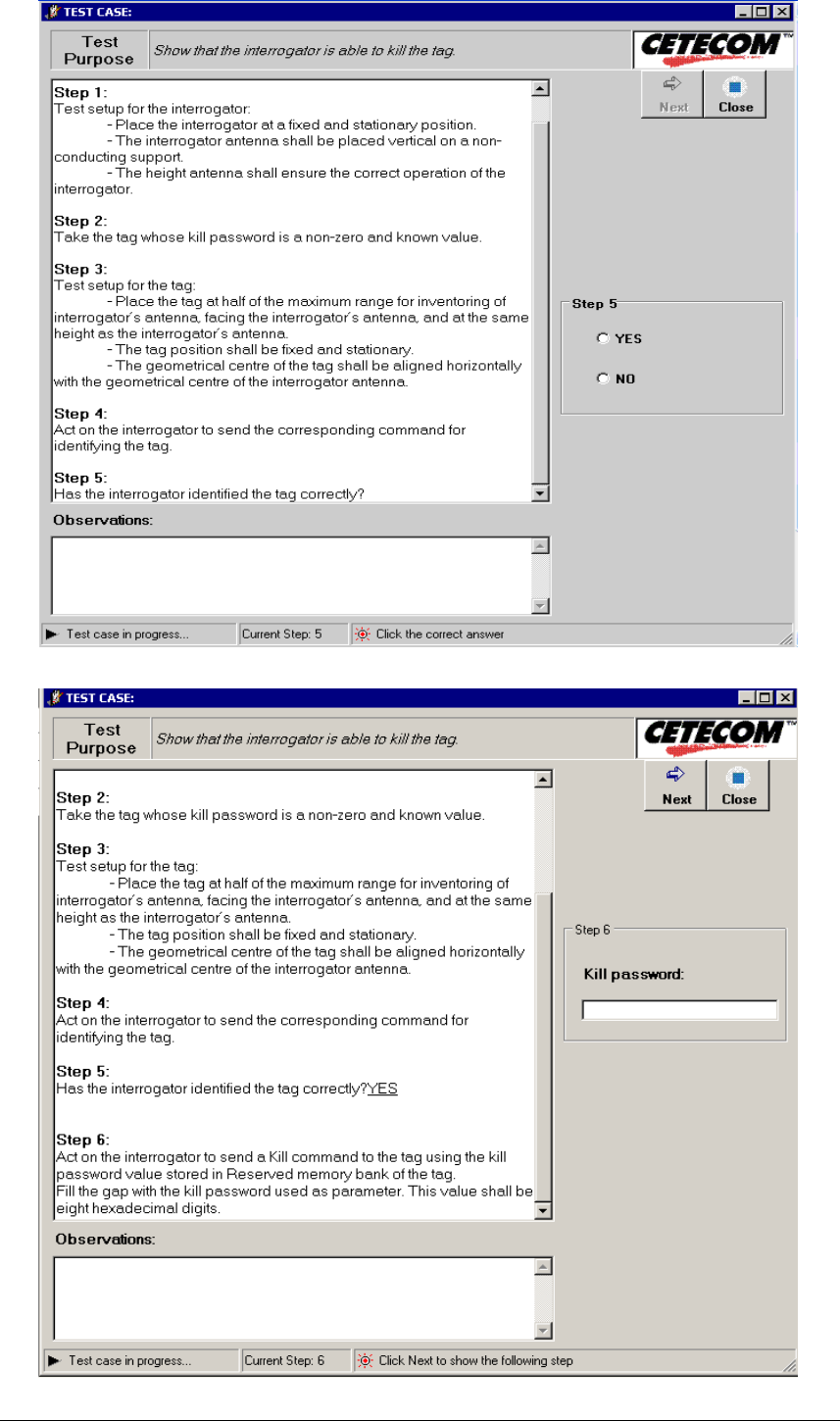

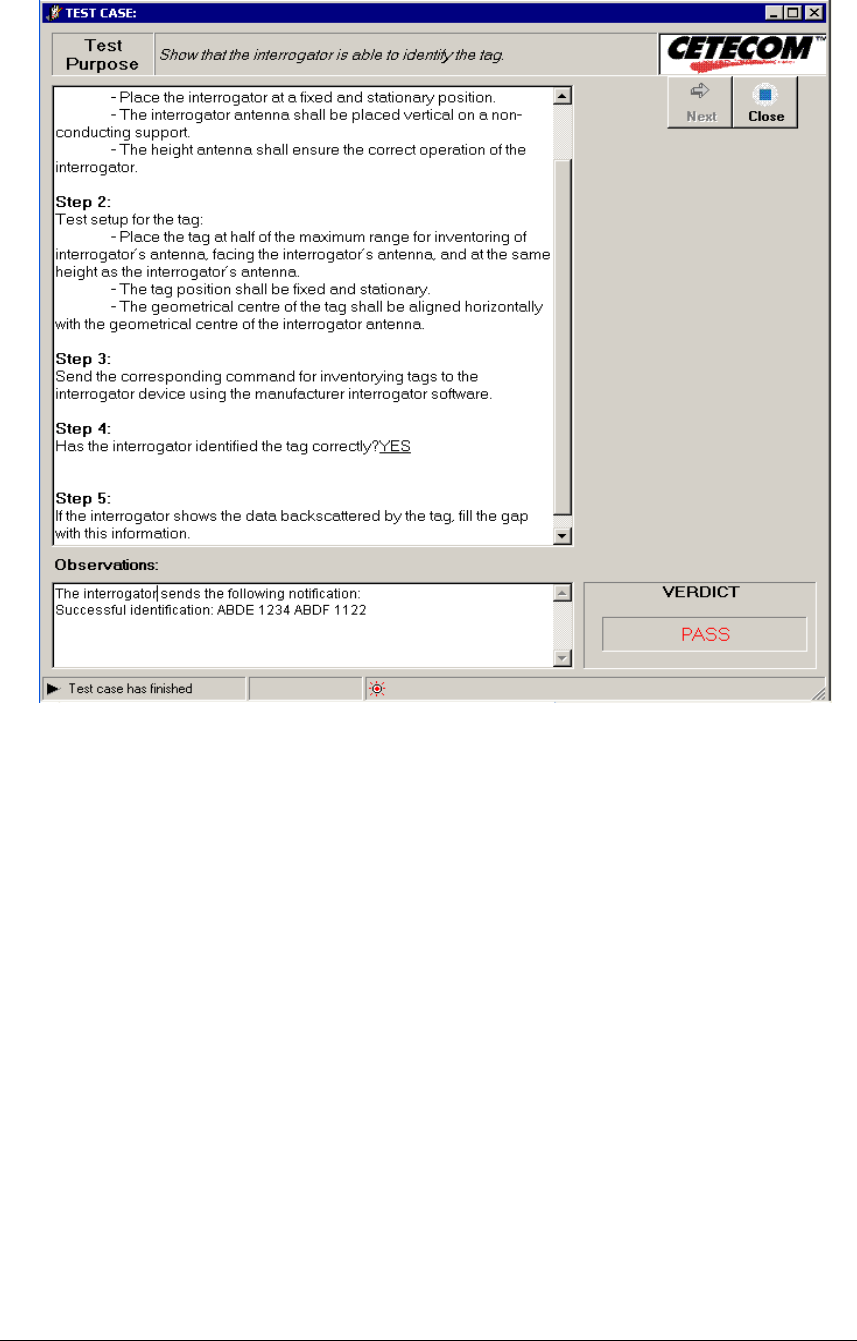

D.8 Test Manager and Sequencer Modules .........................................................................78

D.9 Running Individual Test Cases ......................................................................................82

Date: 2006-08-04 Version 1.2.4 Page 5 of 84

Interoperability Test System for EPC compliant Class-1 Gen-2 UHF RFID

Tables

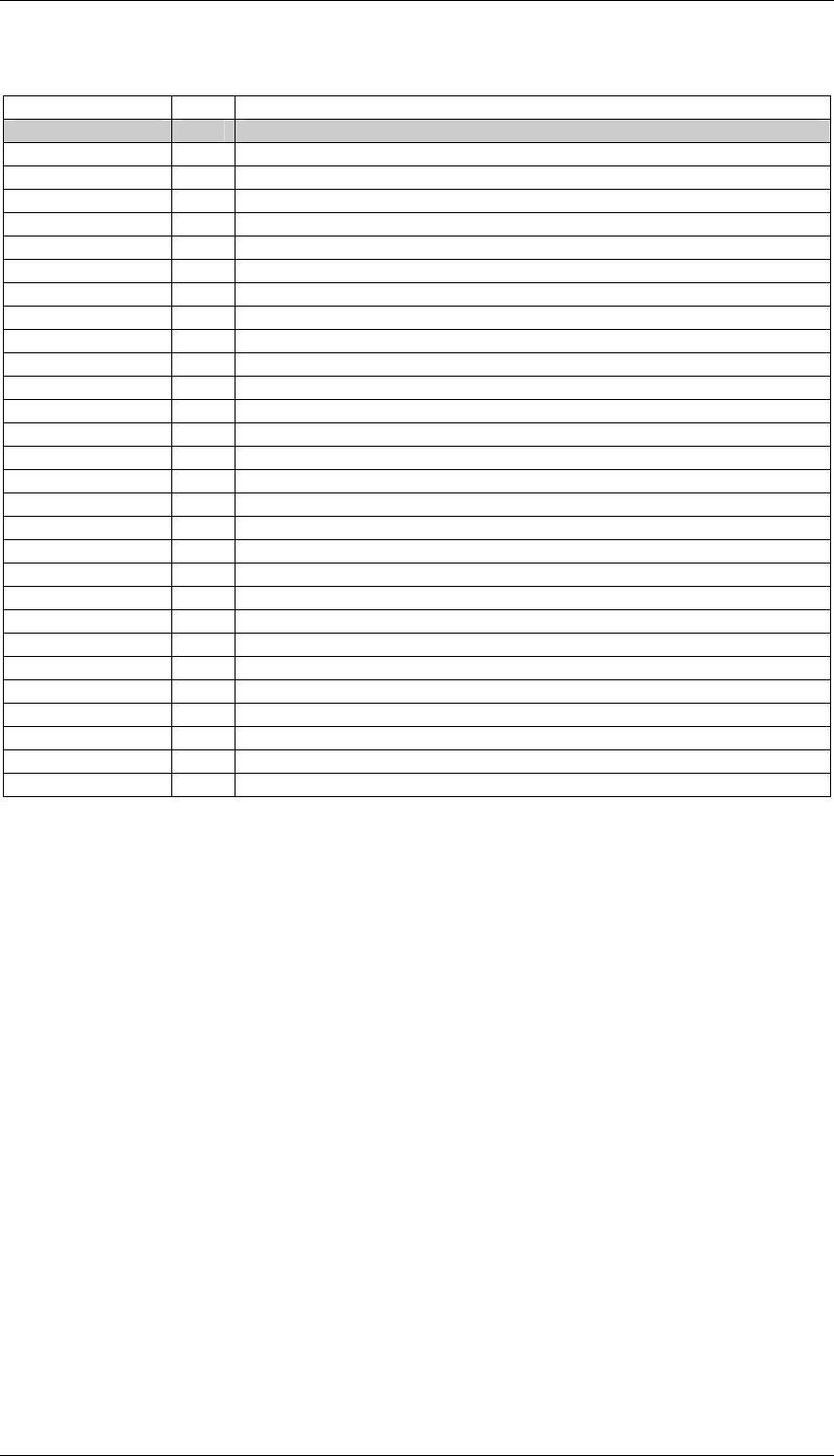

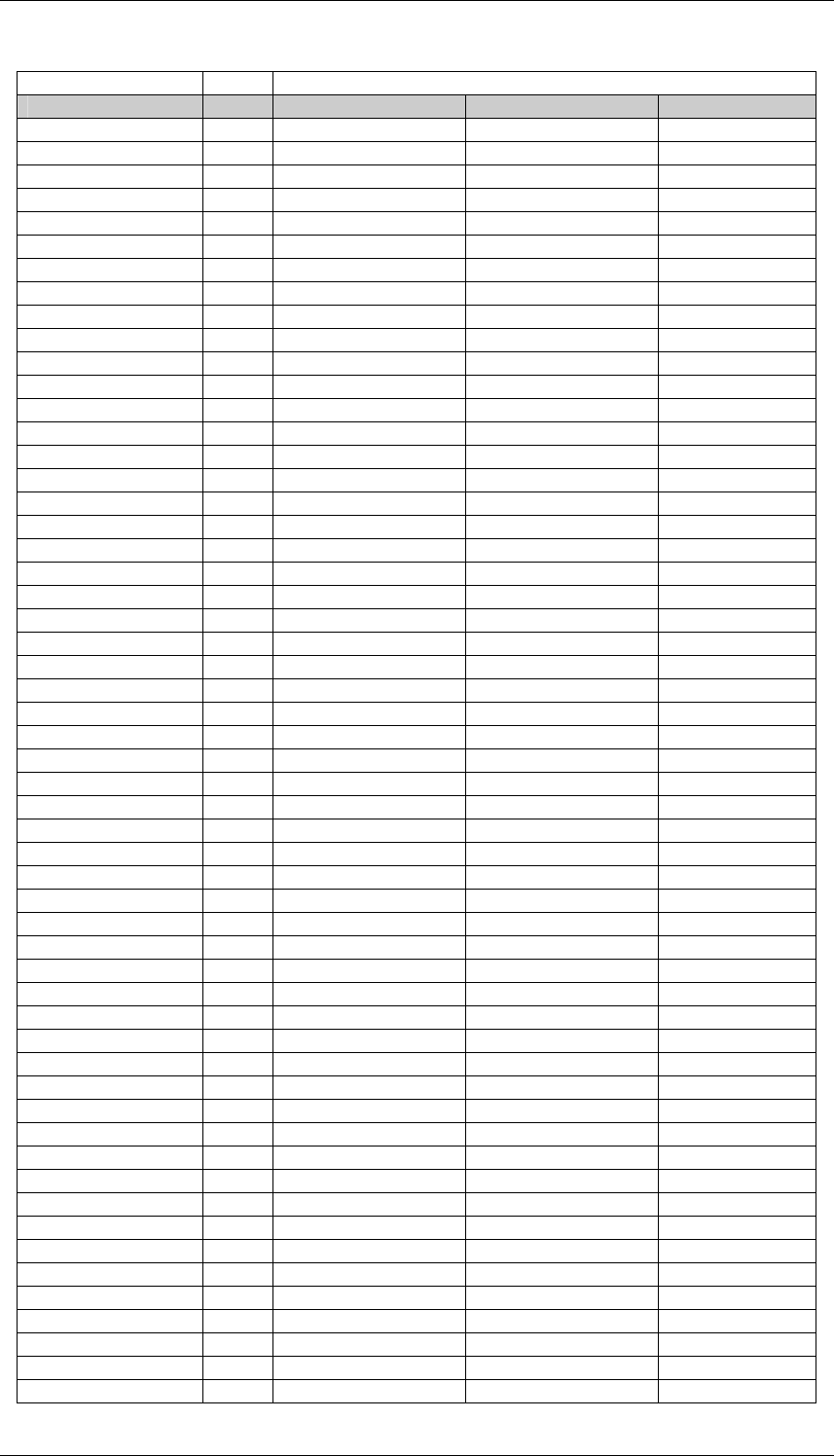

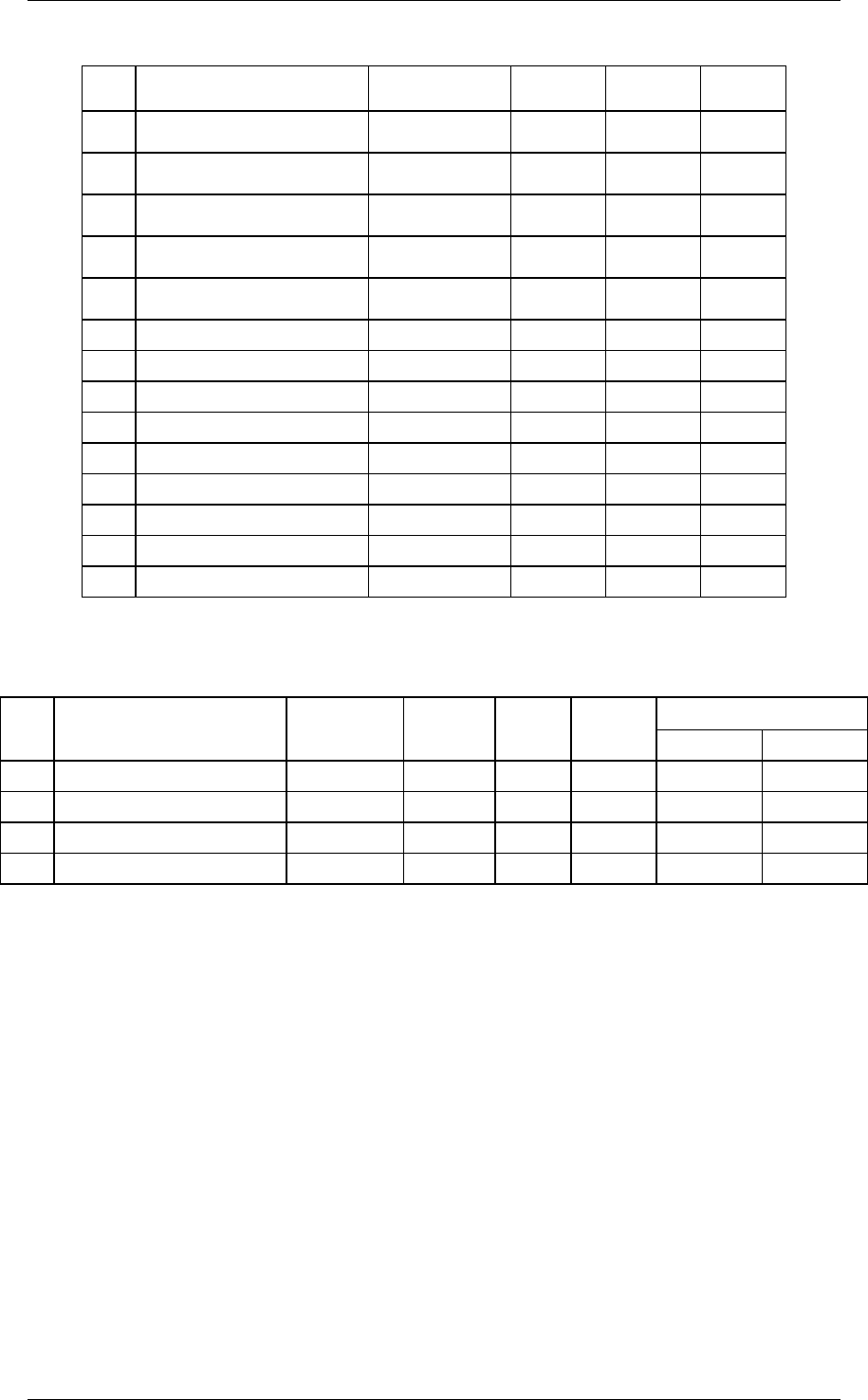

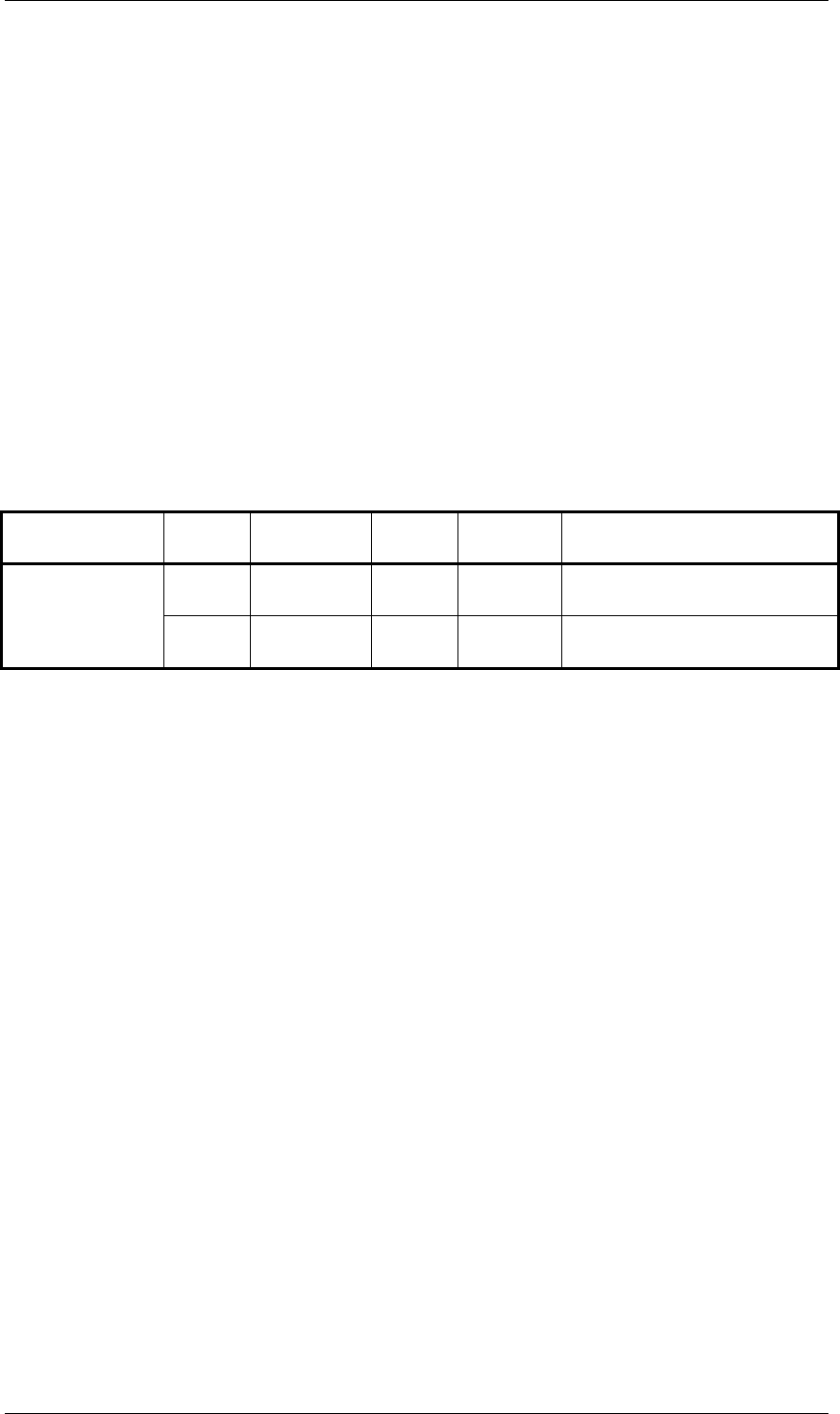

Table 1. Approximate Test Case Identifier ..................................................................................12

Table 2. Kill Password Test Cases ...............................................................................................13

Table 3. EPC Memory Test Cases................................................................................................14

Table 4. TID Memory Test Cases ................................................................................................15

Table 5. User Memory Test Cases ...............................................................................................16

Table 6. Access Test Cases...........................................................................................................18

Table 7. Select/Inventory Test Cases ...........................................................................................18

Table 8. Select/Query Test Cases.................................................................................................20

Table 9. Select/ Query Action ......................................................................................................20

Table A.1. Roles............................................................................................................................42

Table A.2. Basic operations and capabilities for managing tag populations................................42

Table A.3. Commands supported.................................................................................................43

Table A.4. Memory banks supported ...........................................................................................44

Table A.5. Stored passwords in Reserved memory bank.............................................................44

Table A.6. Stored data in EPC memory bank ..............................................................................44

Table A.7. Object identifier type..................................................................................................44

Table A.8. Stored data in TID memory bank................................................................................45

Table A.9. States............................................................................................................................45

Table A.10. Commands supported................................................................................................46

Table A.11. Logical partitioning of the memory banks ................................................................46

Table A.12. Memory locations of stored data in each memory bank............................................47

Table C.1 Manufacturer product summary....................................................................................58

Table C.2 Test Cases List Reference............................................................................................61

Figures

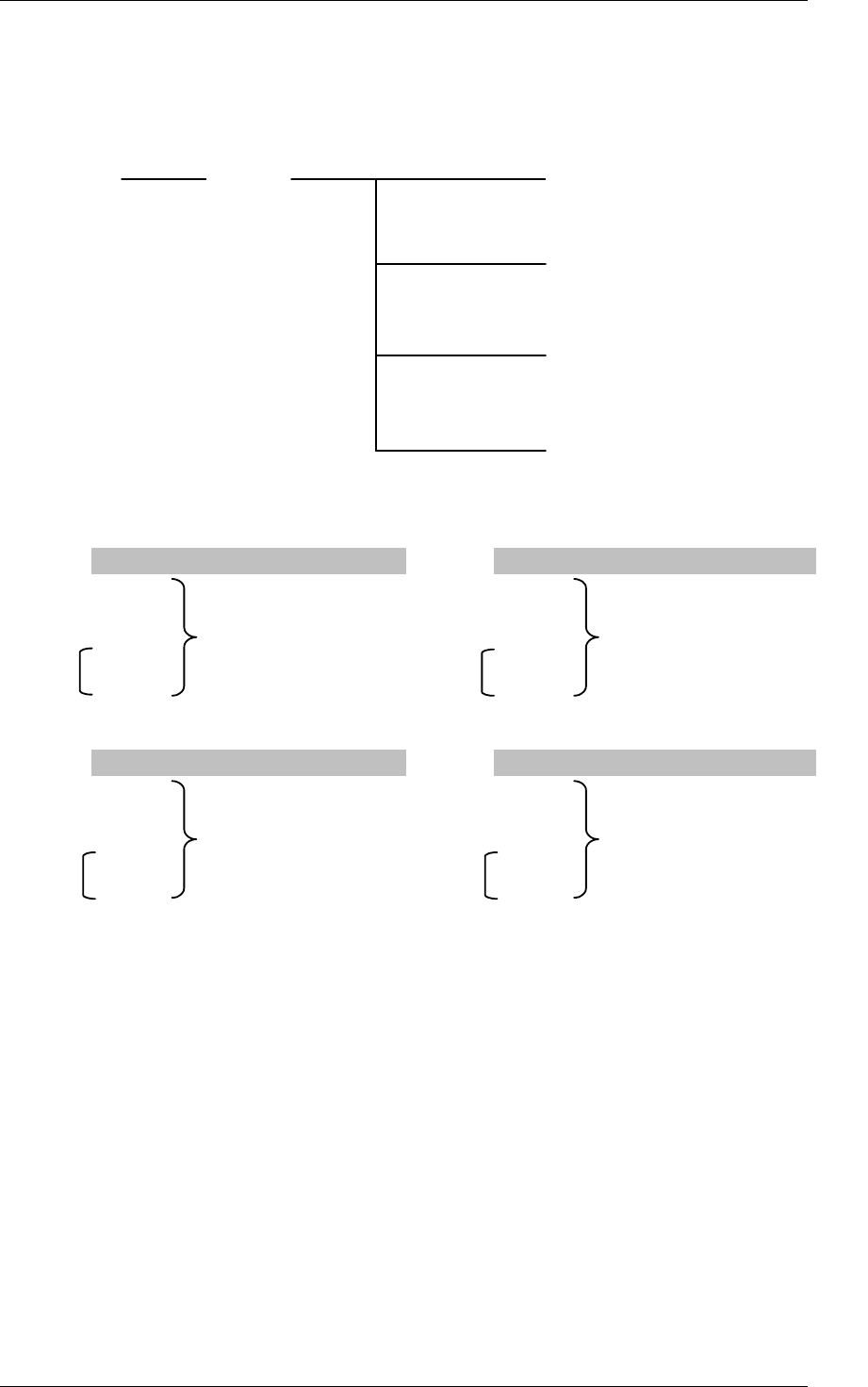

Figure 1. Multi-tag Board.............................................................................................................35

Figure 2. Test Site 1......................................................................................................................35

Figure 3. Test Sites 2 and 3 ..........................................................................................................36

Date: 2006-08-04 Version 1.2.4 Page 6 of 84

Interoperability Test System for EPC compliant Class-1 Gen-2 UHF RFID

1.0 Scope

This document specifies the design of an Interoperability test system for testing that end-to-end

functionality between two communicating RFID hardware devices as required by “EPC

TM

Radio-Frequency Identity Protocols Class-1 Generation-2 UHF RFID Protocol for

Communications at 860 MHZ – 960 MHz. Version 1.0.9”.

The RFID devices under test are interrogators, also known as readers, printers, also known as

encoders, and one or more tags, also known as labels. Tags can be passive, meaning that they

receive all of their operating energy from the interrogator’s RF waveform. They can also be

semi-passive, or active provided the utilized integrated circuit (IC) is compliant to the above

referenced specification. The protocol is interrogator-talks-first (ITF), meaning that a tag

modulates its antenna reflection coefficient with an information signal only after being directed

to do so by an interrogator.

2.0 References

The following documents contain provisions which, through reference in this text, constitute

provisions of the present document.

• References are either specific (identified by date of publication, edition number,

version number, etc) or non-specific.

• For a specific reference, subsequent revisions do not apply.

• For a non-specific reference, the latest version applies.

[1] EPCglobal, Inc.

“EPC

TM

Radio-Frequency Identity Protocols Class-1 Generation-2 UHF

RFID Protocol for Communications at 860 MHZ – 960 MHz. Version 1.0.9”, December

2004.

[2] EPCglobal, Inc.

“EPC

TM

Tag Data Standards”

[3] EPCglobal

TM

(2004): FMCG RFID Physical Requirements Document (draft)

[4] ISO/IEC 15961: Information technology-Radio frequency identification (RFID) for item

management-Data protocol: application interface.

[5] ISO/IEC 15962: Information technology-Radio frequency identification (RFID) for item

management-Data protocol: data encoding rules and logical memory functions.

[6] ISO/IEC 15963: Automatic Identification- Radio Frequency Identification for item

management-Unique identification for RF tag.

[7] ISO/IEC 9646-1: Information technology - Open Systems Interconnection - Conformance

testing methodology and framework - Part 1: General concepts.

[8] ISO/IEC 9646-2: Information technology - Open Systems Interconnection - Conformance

testing methodology and framework - Part 2: Abstract Test Suite specification.

[9] ETSI ETS 300 406: Methods for Testing and Specification (MTS); Protocol and Profile

Conformance Testing specifications; Standardization methodology.

[10] ETSI TS 102 237-1 v 4.1.1 (2003-12): Telecommunications and Internet Protocol

Harmonization Over Networks (TIPHON) Release 4; Interoperability test methods and

approaches; Part 1: Generic approach to interoperability testing.

[11] Interoperability Test System for EPC compliant devices Class-1 Generation-2 UHF RFID

devices. Requirements for the Interop tester v1.0 CETECOM

Date: 2006-08-04 Version 1.2.4 Page 7 of 84

Interoperability Test System for EPC compliant Class-1 Gen-2 UHF RFID

3.0 Definitions and Abbreviations

3.1 Definitions

For the purposes of the present document, the following terms and definitions apply:

Interoperability: Ability of two or more systems or devices to exchange information using the

same communication protocol.

Interoperability testing: Activity of testing end-to-end functionality between (at least) two

communicating systems as required by the standard(s) on which those systems are based.

Reference specification: A standard, which specifies a base specification, or a set of base

specifications, or a profile, or a set of profiles, and for conformance against which test

specifications are written.

Interrogator samples for interoperability testing: A device which combines both

transmission and reception capabilities within a single housing. Its components are an antenna, a

RFID reader and suitable control software to evaluate interrogator performance.

Tag samples for interoperability testing: RFID tags contain an antenna and an electronic

microchip to enable them to receive and respond to radio-frequency queries from an RFID

transceiver. A minimum sample size is required to complete testing since some will be

permanently altered in the course of testing.

Test Purpose (TP): Easy-to-read description of each test, concentrating on the meaning of the

test rather than detailing how it may be achieved. The Test Purpose is derived from the

reference specification and focuses on testing a specific functionality of the EUT (Equipment

Under Test i.e. reader or tag) that can be affected at the user interfaces offered by the SUT

(System Under Test).

Test Suite: A major subset of the Gen2 protocol. A test suite is verified by running a number of

like test cases. A simple scripting language can be used to sequence through the test cases. The

script links to a reader application that issues commands and collects responses from the tag.

Success/failure for each test case is determined by comparing the responses to the expected

responses.

Test Case: A fundamental functionality within the Gen2 protocol, for instance, reading the

Access password. Test cases are grouped in order to verify a test suite. All test cases within a

test suite must be successful in order for the suite to be declared successfully verified. Test cases

may require more than one reader command to be verified. For example, a Write test case is

verified only after a subsequent Read. The Write and Read can be mated in a script to

accomplish this.

Interoperability Statement (IS): A checklist of the capabilities/functionalities supported by

the EUT is used to select and parameterize test cases and as an indicator of interoperability

between different products.

Implementation eXtra Information for Testing (IXIT): Contains additional information

(e.g., specific addresses, timer values, etc.) necessary for testing.

Equipment Under Test (EUT): An interrogator, a tag or a tag population. The subject of the

test may be a single EUT, which is testing against a QE, or another EUT.

Qualified Equipment (QE): A device that has been shown, by rigorous and well-defined

testing, to operate with other equipment and adhere to the protocol.

Date: 2006-08-04 Version 1.2.4 Page 8 of 84

Interoperability Test System for EPC compliant Class-1 Gen-2 UHF RFID

System Under Test (SUT): One or more EUTs and /or QEs. For the purposes of the present

document, the SUT may comprise one or more QEs and a single EUT, or possibly two EUTs,

depending on the selected test scenario. In all cases the test scenario shall be comprised of at

least one interrogator and one tag.

3.2 Abbreviations

For the purposes of the present document, the following abbreviations apply:

AFI Application Family Identifier

AP Access password

CRC Cyclic Redundancy Check

E EPC Memory

EN-RT European Normative Requirements Table

EPC Electronic Product Code

ETSI European Telecommunications Standards Institute

Handle 16-bit Tag-authentication number

I Inventory

IS Implementation Statement

ITF Interrogator Talks First (Reader Talks First)

IXIT Implementation eXtra Information for Testing

K Kill

KP Kill password

L Locked

M Mandatory, shall be implemented under all circumstances

MH Multiple Homogeneous populations of tags

MM Multiple Mixed population of tags

MTR Message Transfer

NSI Numbering System Identifier

O Optional, may be provided, but if provided shall be implemented in accordance with

the requirements

O.n This status is used for mutually exclusive or selectable options among a set. The

integer "n" shall refer to a unique group of options within the EN-RT. A footnote to

the EN-RT shall explicitly state what the requirement is for each numbered group.

For example, "It is mandatory to support at least one of these options", or, "It is

mandatory to support exactly one of these options".

PC Protocol Control

PL Permanently locked (Permalocked)

PU Permanently unlocked

R Read

RFID Radio-Frequency IDentification

RFU Reserved for Future Use

RN16 16-bit Random or pseudo-Random Number

RNG Random or pseudo-Random Number Generator

SI Select/Inventory

SQ Select/Query

SUT System Under Test

T TID memory

TBD To Be Defined

TID Tag-IDentification or Tag-Identifier, depending on context

TP Test Purpose

TSS Test Suite Structure

U User memory

UHF Ultra High Frequency

V Valid

W Write

Word 16 bits

Date: 2006-08-04 Version 1.2.4 Page 9 of 84

Interoperability Test System for EPC compliant Class-1 Gen-2 UHF RFID

4.0 Procedures

4.1 Procedures

Interoperability testing can be defined as the functional testing of a product against another

operational product according to a set of test specifications. Interoperability tests are based on

functionality as experienced by the user (i.e., they are not necessarily specified at the protocol

level). Also the interoperability tests are performed at interfaces that offer normal user control

and observation.

The described test system will provide the user’s interfaces and other facilities for

interoperability testing and reduce testing time. As a means of improving testing coverage,

efficiency and consistency, a scripting language is specified that allows test cases to be

concatenated and run automatically. An output file is created that contains the test results

thereby easing documentation.

The test system procedures are:

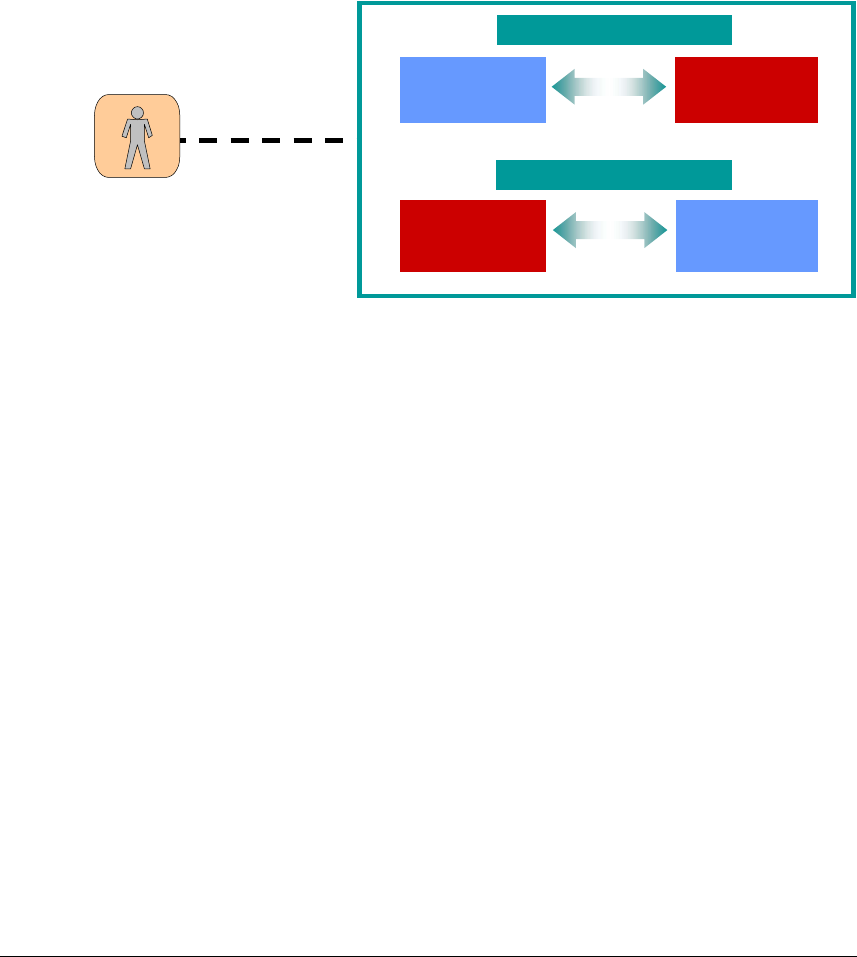

1. The interoperability test system allows choosing between two options for testing:

A. EUT - EUT (EUT against EUT)

Both, reader and tag are EUTs and both devices are tested to interoperate.

B. EUT - QE (EUT against QE)

Qualified Equipment may be a reader, a tag or a population of tags depending

on the device under test.

Date: 2006-08-04 Version 1.2.4 Page 10 of 84

Interoperability Test System for EPC compliant Class-1 Gen-2 UHF RFID

5.0 Test Suite Design

5.1 Test Suite Overview

Test Suites are created by assembling a group of test cases that exercise a major functionality

subset of the Gen2 protocol. For interoperability coverage four Test Suites have been defined;

Select/Inventory, Memory Access, Permalock/Kill, and Special. The set of Test Suites is run

for a given reader/tag air interface condition. The set of parameters that define the air interface

settings is called the mode. A mode defines the reader-to-tag characteristics (Modulation type,

Tari, PIE) and the tag-to-reader characteristics (LF, M, DR, TRext). If a reader supports more

than one mode, the bounding modes (longest and shortest Tari’s) shall be tested. The pseudo-

code below illustrates the testing hierarchy used to show interoperability.

Mode (Mod type/Tari/PIE/LF/M/DR/TRext)

Select/Inventory (Non-select inventory, Select inventory)

Multi-tag (homogeneous, mixed)

Memory (EPC, TID, User)

Single tag

Memory (EPC, TID, User)

Lock (Unlocked, Locked, Permaunlocked, Permalocked)

Select/Query (memory bank, session flags, actions, mask, truncate)

END Select/Inventory

Memory access (unsecured, secured)

Memory (Passwords, EPC, TID, User)

Lock (Unlocked, Locked, Permaunlocked, Permalocked)

Permalock/kill

Memory (Passwords, EPC, TID, User)

Lock (Permaunlocked, Permalocked)

Special

Slot counter (ACK, don’t ACK)

END Mode

The Select/Inventory suite verifies that a sub-population of tags can be selectively inventoried

and that the Select command elicits the proper response from the tag. Multi and single tag

testing is performed to verify the Select and Inventory functions within the protocol.

The Memory Access suite confirms that tag memory can be appropriately accessed. Memory

access through the secured and unsecured state diagram paths are exercised. Access is evaluated

with memories pre-configured in the each of their possible four states; unlocked, locked,

permaunlocked or permalocked.

The Permalock/Kill suite tests the memories in their permaunlocked and permalocked states.

Once permalock testing is completed, the tag’s Kill functionality is verified. This suite is

separated so that the number of tags permanently altered is minimized.

The Special suite is reserved for miscellaneous tests that don’t fall in the other suites. Once

example is a test of the tag slot counter where it is assured that the tag responds only once

within an inventory round and remains silent to continue QueryReps after it has been singulated.

It is expected that additional tests will be discovered that fall within this important suite.

Date: 2006-08-04 Version 1.2.4 Page 11 of 84

Interoperability Test System for EPC compliant Class-1 Gen-2 UHF RFID

5.2 Test Cases

Read, Write, Lock, Select, and Inventory test cases are listed in the tables with this section. A

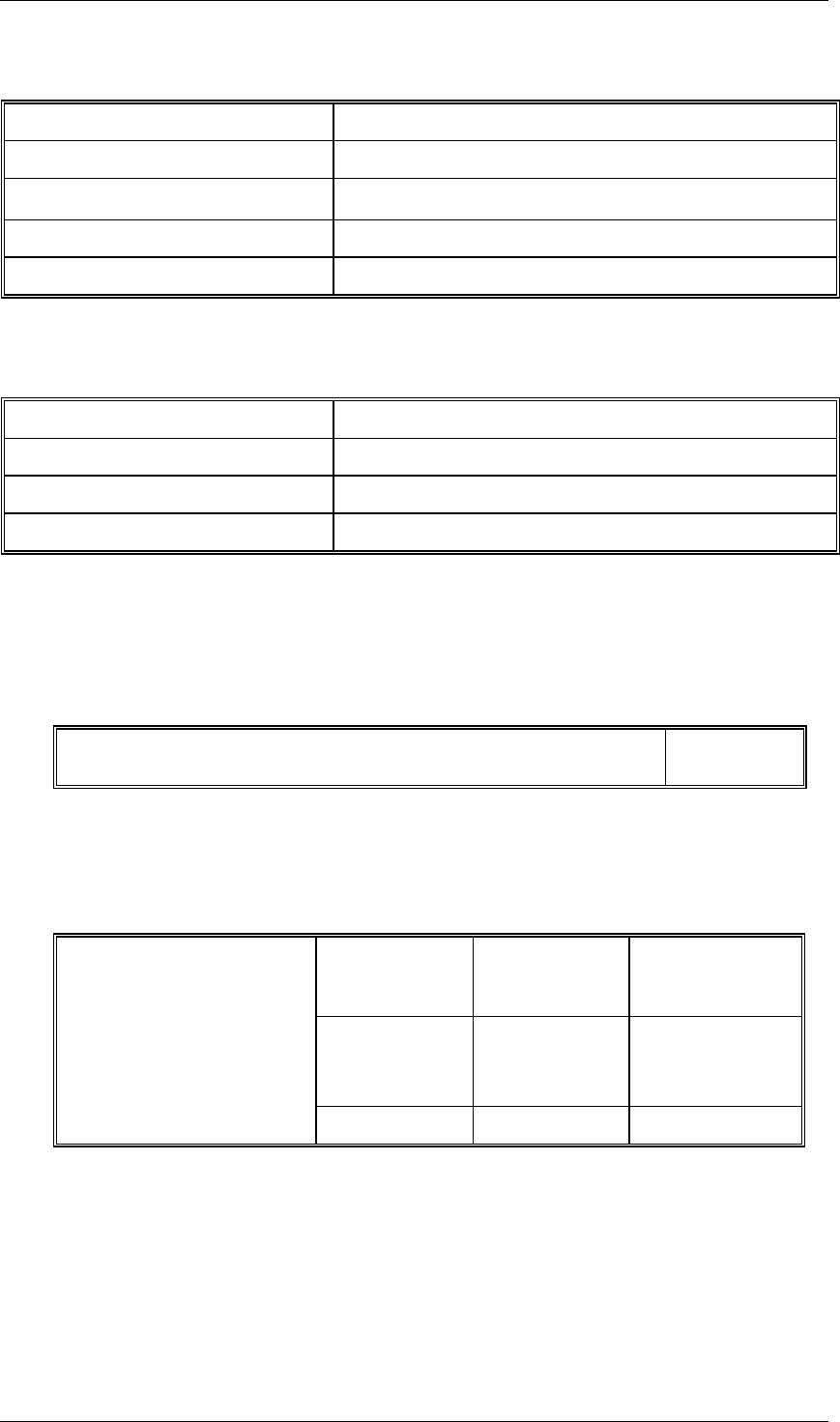

test case identifier is assigned to each test case using the approximate syntax described in the

following table. All of the test cases shall be exercised within at least one of the Test Suites for

each mode to assure interoperability coverage.

Approximate Test Case identifier naming convention scheme

Identifier: <functionality under test>_<memory targeted>_<memory state>_<memory action>_<nn>

<functionality under test> I (Inventory)

SI (Select then Inventory)

SQ (Select then Query)

W (Write)

L (Lock)

U (Unlock)

PL (Permalock)

PU (Permaunlock)

K (Kill)

R (Read)

<memory targeted> AP (Access Password)

KP (Kill Password)

E (EPC Memory)

T (TID Memory)

U (User Memory)

MH (Multiple homogenous population)

MM (Multiple mixed population)

<memory state> (Unlocked)

L (Locked)

PL (Permalocked)

PU (Permaunlocked)

P (Partial, change portion of memory)

C (Complete, change complete memory)

<memory action> Z (Write zero value)

NZ (Write non-zero value)

<nn> sequential number (1-99)

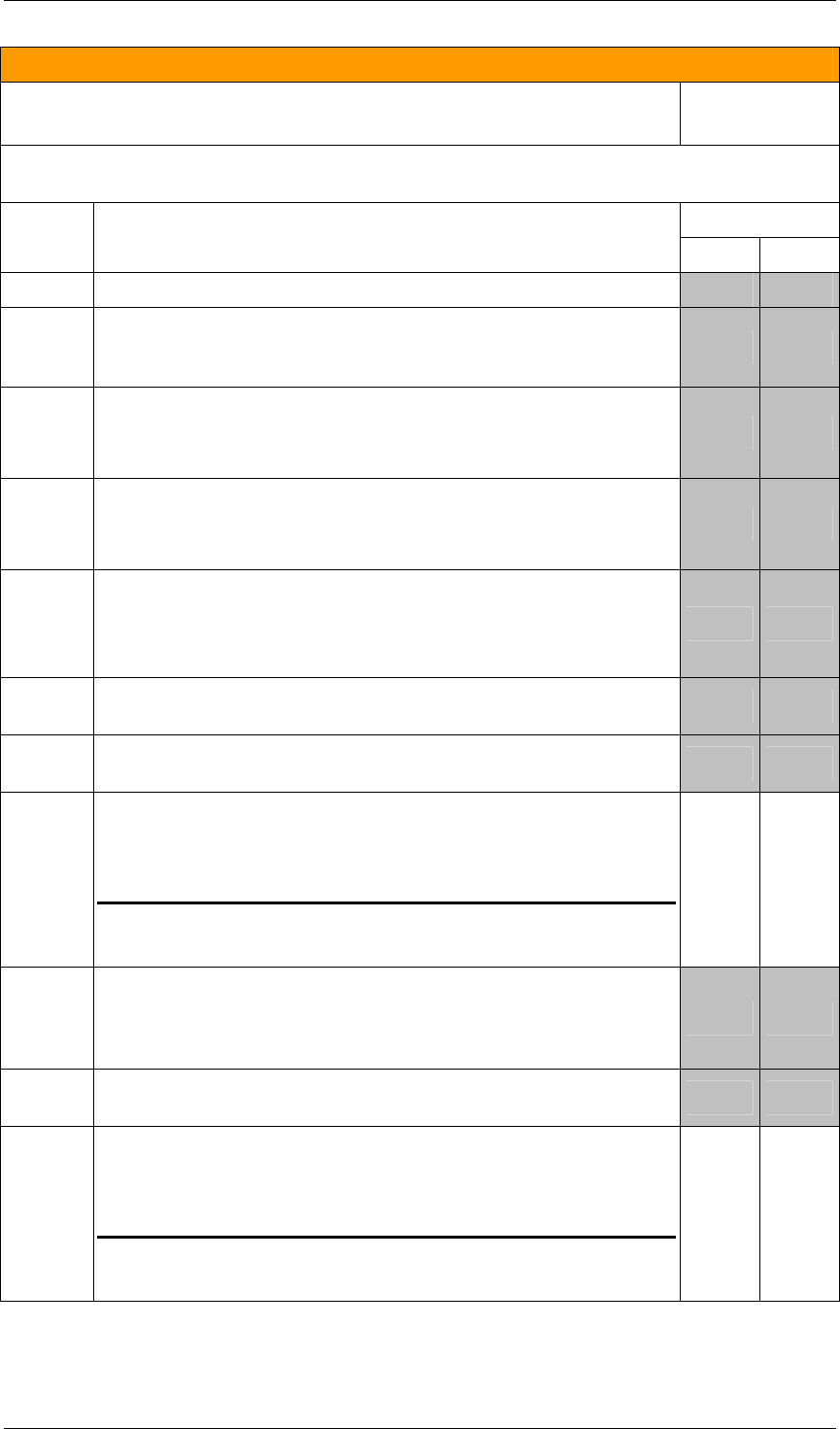

Table 1. Approximate Test Case Identifier

Date: 2006-08-04 Version 1.2.4 Page 12 of 84

Interoperability Test System for EPC compliant Class-1 Gen-2 UHF RFID

Kill Password Verify kill password operations are correctly performed

Test case Lock Action

R_KP Kill password

R_KP_L L Kill password

R_KP_PU PU Kill password

R_KP_PL_1 PL Kill password; Access password zero

R_KP_PL_2 PL Kill password; Access password non-zero

W_KP_Z Kill password zero

W_KP_NZ Kill password non-zero

W_KP_L_NZ L Kill password non-zero

W_KP_PU_NZ PU Kill password non-zero

W_KP_PL_NZ_1 PL Kill password non-zero; Access password zero

W_KP_PL_NZ_2 PL Kill password non-zero; Access password non-zero

L_KP Kill password

PU_KP Kill password

PL_KP Kill password; Same command as a L_KP and a PU_KP

U_KP_L L Kill password

PL_KP_L_1 L Kill password; Access password zero

PL_KP_L_2 L Kill password; Access password non-zero

U_KP_PU PU Kill password

L_KP_PU PU Kill password

PU_KP_PU PU Kill password

U_KP_PL_1 PL Kill password; Access password zero

U_KP_PL_2 PL Kill password; Access password non-zero

L_KP_PL_1 PL Kill password; Access password zero

L_KP_PL_2 PL Kill password; Access password non-zero

PU_KP_PL_1 PL Kill password; Access password zero

PU_KP_PL_2 PL Kill password; Access password non-zero

K_Z Kill zero password

K_INZ Kill incorrect non-zero password

K_INZ_L L Kill incorrect non-zero password

K_INZ_PU PU Kill incorrect non-zero password

K_INZ_PL PL Kill incorrect non-zero password

K_NZ Kill non-zero password

Table 2. Kill Password Test Cases

Date: 2006-08-04 Version 1.2.4 Page 13 of 84

Interoperability Test System for EPC compliant Class-1 Gen-2 UHF RFID

EPC memory Verify EPC memory operations are correctly performed

Test case Lock Action

R_E_C EPC complete

R_E_P EPC partial

R_E_L_P L EPC partial

R_E_PU_P PU EPC partial

R_E_PL_P_1 PL EPC partial; Access password zero

R_E_PL_P_2 PL EPC partial; Access password non-zero

W_E_C EPC complete

W_E_P EPC partial

W_E_L_P L EPC partial

W_E_PU_P PU EPC partial

W_E_PL_P_1 PL EPC partial; Access password zero

W_E_PL_P_2 PL EPC partial; Access password non-zero

L_E EPC memory

PU_E EPC memory

U_E_L L EPC memory

PL_E_L_1 L EPC memory; Access password zero

PL_E_L_2 L EPC memory; Access password non-zero

U_E_PU PU EPC memory

L_E_PU PU EPC memory

PU_E_PU PU EPC memory

U_E_PL_1 PL EPC memory; Access password zero

U_E_PL_2 PL EPC memory; Access password non-zero

L_E_PL_1 PL EPC memory; Access password zero

L_E_PL_2 PL EPC memory; Access password non-zero

PU_E_PL_1 PL EPC memory; Access password zero

PU_E_PL_2 PL EPC memory; Access password non-zero

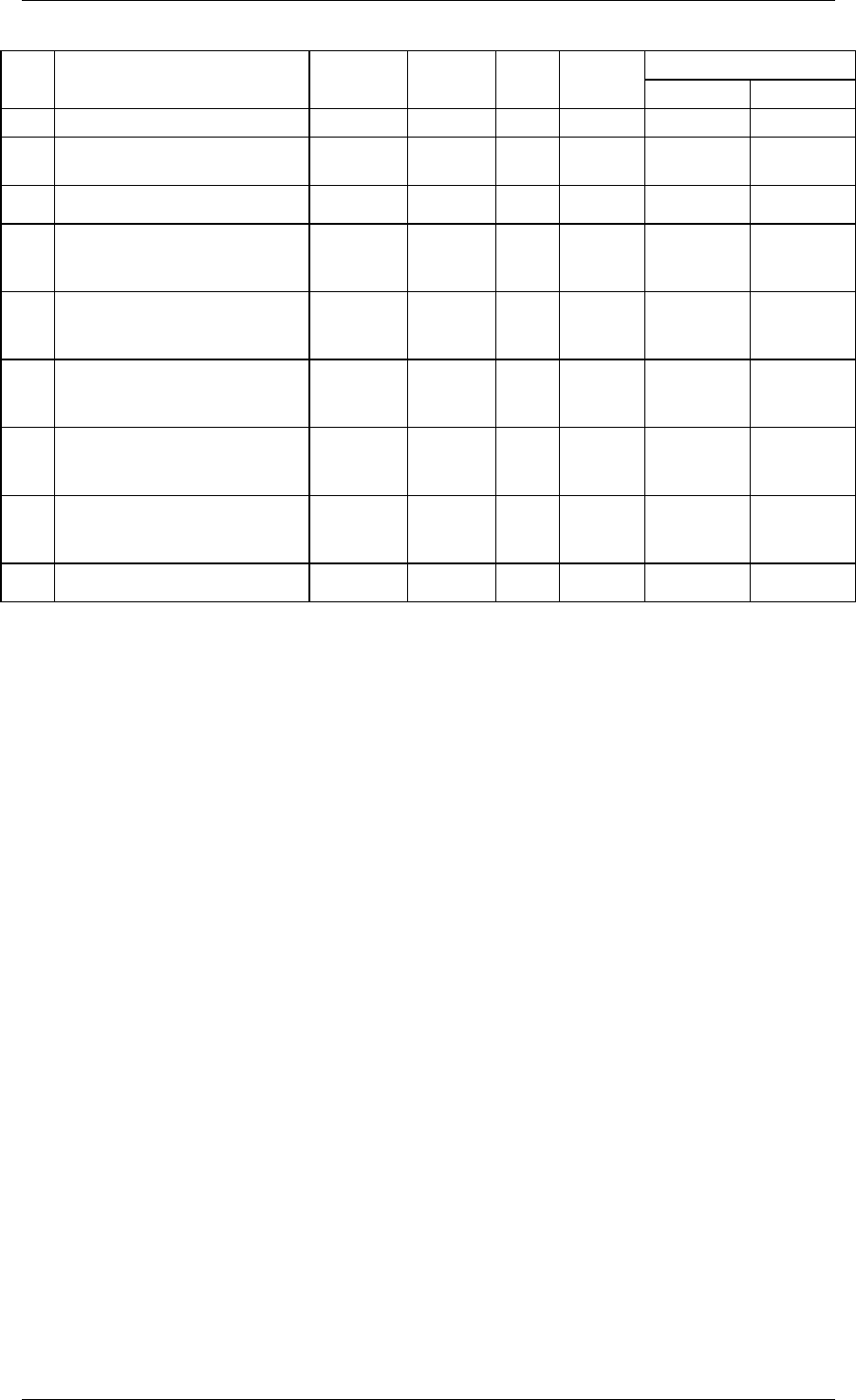

Table 3. EPC Memory Test Cases

Date: 2006-08-04 Version 1.2.4 Page 14 of 84

Interoperability Test System for EPC compliant Class-1 Gen-2 UHF RFID

TID memory Verify TID memory operations are correctly performed

Test case Lock Action

R_T_C TID complete

R_T_P TID partial

R_T_L_P L TID partial

R_T_PU_P PU TID partial

R_T_PL_P_1 PL TID partial; Access password zero

R_T_PL_P_2 PL TID partial; Access password non-zero

W_T_C TID complete

W_T_P TID partial

W_T_L_P L TID partial

W_T_PU_P PU TID partial

W_T_PL_P_1 PL TID partial; Access password zero

W_T_PL_P_2 PL TID partial; Access password non-zero

L_T TID memory

PU_T TID memory

U_T_L L TID memory

PL_T_L_1 L TID memory; Access password zero

PL_T_L_2 L TID memory; Access password non-zero

U_T_PU PU TID memory

L_T_PU PU TID memory

PU_T_PU PU TID memory

U_T_PL_1 PL TID memory; Access password zero

U_T_PL_2 PL TID memory; Access password non-zero

L_T_PL_1 PL TID memory; Access password zero

L_T_PL_2 PL TID memory; Access password non-zero

PU_T_PL_1 PL TID memory; Access password zero

PU_T_PL_2 PL TID memory; Access password non-zero

Table 4. TID Memory Test Cases

Date: 2006-08-04 Version 1.2.4 Page 15 of 84

Interoperability Test System for EPC compliant Class-1 Gen-2 UHF RFID

User memory Verify user memory operations are correctly performed

Test case Lock Action

R_U_C User complete

R_U_P User partial

R_U_P_L L User partial

R_U_P_PU PU User partial

R_U_P_PL_1 PL User partial; Access password zero

R_U_P_PL_2 PL User partial; Access password non-zero

W_U_C User complete

W_U_P User partial

W_U_L_P L User partial

W_U_PU_P PU User partial

W_U_PL_P_1 PL User partial; Access password zero

W_U_PL_P_2 PL User partial; Access password non-zero

L_U User memory

PU_U User memory

U_U_L L User memory

PL_U_L_1 L User memory; Access password zero

PL_U_L_2 L User memory; Access password non-zero

U_U_PU PU User memory

L_U_PU PU User memory

PU_U_PU PU User memory

U_U_PL_1 PL User memory; Access password zero

U_U_PL_2 PL User memory; Access password non-zero

L_U_PL_1 PL User memory; Access password zero

L_U_PL_2 PL User memory; Access password non-zero

PU_U_PL_1 PL User memory; Access password zero

PU_U_PL_2 PL User memory; Access password non-zero

Table 5. User Memory Test Cases

Date: 2006-08-04 Version 1.2.4 Page 16 of 84

Interoperability Test System for EPC compliant Class-1 Gen-2 UHF RFID

Access Verify access operations are correctly performed

Test case Lock AP Action AP State AP

R_AP_1 - zero Correct

R_AP_2 - zero Incorrect

R_AP_3 - non-zero Correct

R_AP_4 - non-zero Incorrect

R_AP_5 - non-zero None

R_AP_L_1 L - zero Correct

R_AP_L_2 L - zero Incorrect

R_AP_L_3 L - non-zero Correct

R_AP_L_4 L - non-zero Incorrect

R_AP_L_5 L - non-zero None

R_AP_PU_1 PU - zero Correct

R_AP_PU_2 PU - zero Incorrect

R_AP_PU_3 PU - non-zero Correct

R_AP_PU_4 PU - non-zero Incorrect

R_AP_PU_5 PU - non-zero None

R_AP_PL_1 PL - non-zero Correct

R_AP_PL_2 PL - non-zero None

W_AP_Z zero non-zero Correct

W_AP_NZ_1 non-zero zero Correct

W_AP_NZ_2 non-zero non-zero Correct

W_AP_NZ_3 non-zero non-zero Incorrect

W_AP_NZ_4 non-zero non-zero None

W_AP_L_NZ_1 L non-zero zero Correct

W_AP_L_NZ_2 L non-zero zero Incorrect

W_AP_L_NZ_3 L non-zero non-zero Correct

W_AP_L_NZ_4 L non-zero non-zero Incorrect

W_AP_L_NZ_5 L non-zero non-zero None

W_AP_PU_Z PU zero non-zero Correct

W_AP_PU_NZ_1 PU non-zero zero Correct

W_AP_PU_NZ_2 PU non-zero non-zero Correct

W_AP_PU_NZ_3 PU non-zero non-zero Incorrect

W_AP_PU_NZ_4 PU non-zero non-zero None

W_AP_PL_NZ_1 PL non-zero non-zero Correct

W_AP_PL_NZ_2 PL non-zero non-zero None

L_AP_1 - zero Correct

L_AP_2 - zero Incorrect

L_AP_3 - non-zero Correct

L_AP_4 - non-zero Incorrect

L_AP_5 - non-zero None

PU_AP - zero Correct

U_AP_L_1 L - zero Correct

U_AP_L_2 L - zero Incorrect

U_AP_L_3 L - non-zero Correct

U_AP_L_4 L - non-zero Incorrect

PL_AP_L_1 L - non-zero Incorrect

PL_AP_L_2 L - non-zero None

PL_AP_L_3 L - zero Correct

L_AP_PU_1 PU - zero None

L_AP_PU_2 PU - non-zero Correct

L_AP_PU_3 PU - non-zero None

PU_AP_PU_1 PU - zero None

PU_AP_PU_2 PU - non-zero Correct

PU_AP_PU_3 PU - non-zero None

Date: 2006-08-04 Version 1.2.4 Page 17 of 84

Interoperability Test System for EPC compliant Class-1 Gen-2 UHF RFID

U_AP_PL_1 PL - zero Correct

U_AP_PL_2 PL - non-zero Correct

U_AP_PL_3 PL - non-zero None

L_AP_PL_1 PL - zero Correct

L_AP_PL_2 PL - non-zero Correct

L_AP_PL_3 PL - non-zero None

PU_AP_PL_1 PL - zero Correct

PU_AP_PL_2 PL - non-zero Correct

PU_AP_PL_3 PL - non-zero None

Table 6. Access Test Cases

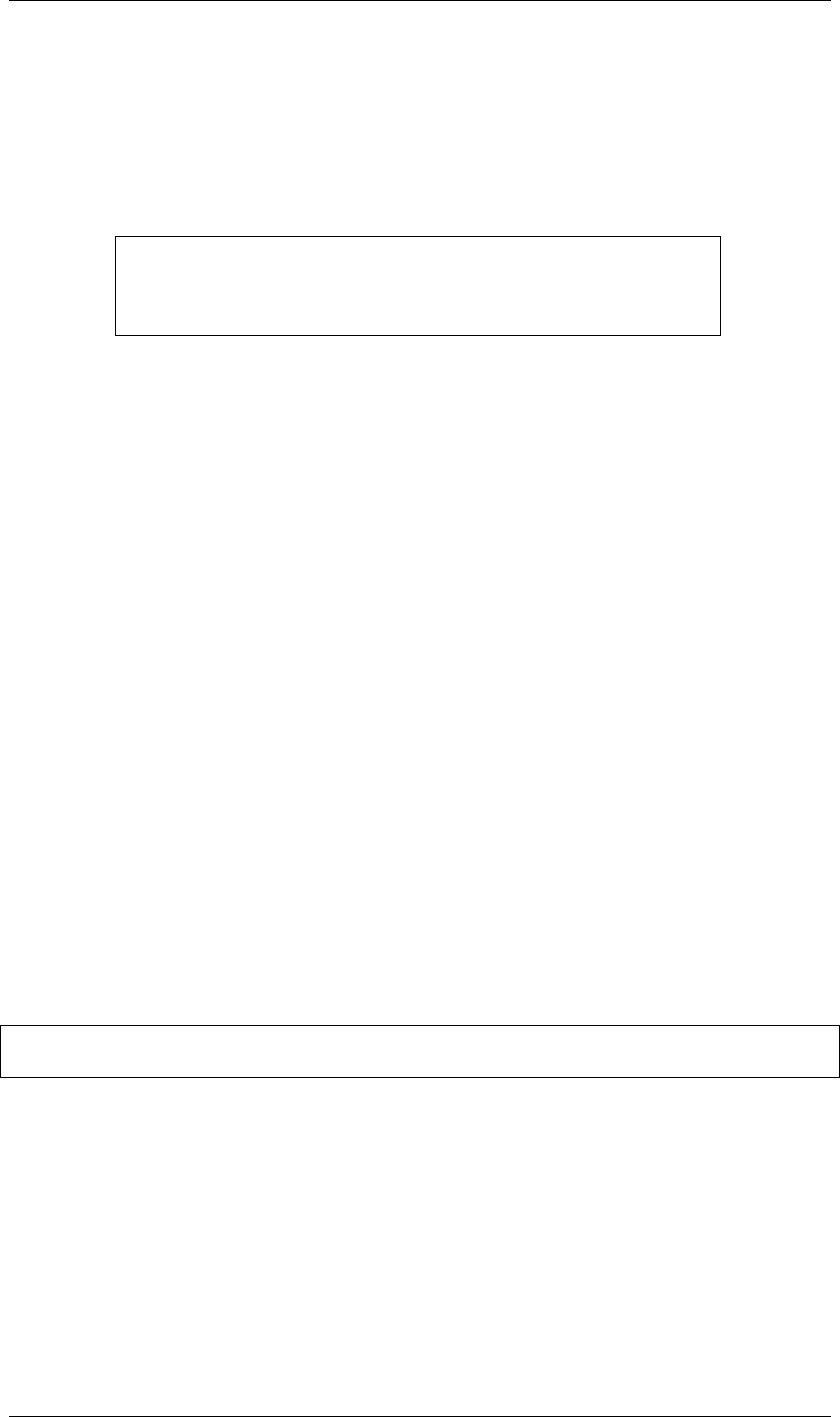

Select/Inventory

Test case Lock Action

Multi-tag Verify ability to inventory all tags or a selected sub-population

I_MH Non-select inventory homogeneous

SI_MH_E Select EPC complete homogeneous

SI_MH_T Select TID complete homogeneous

SI_MH_U Select User complete homogeneous

I_MM Non-select inventory mixed

SI_MM_E Select EPC complete mixed

SI_MM_T Select TID complete mixed

SI_MM_U Select User complete mixed

Single tag Verify ability to Select and Inventory with memories in various lock

states

I Non-select inventory

I_L L Non-select inventory

I_PU PU Non-select inventory

I_PL PL Non-select inventory

SI_E Select EPC complete

SI_E_L L Select EPC partial

SI_E_PU PU Select EPC partial

SI_E_PL PL Select EPC partial

SI_T Select TID complete

SI_T_L L Select TID partial

SI_T_PU PU Select TID partial

SI_T_PL PL Select TID partial

SI_U Select User complete

SI_U_L L Select User partial

SI_U_PU PU Select User partial

SI_U_PL PL Select User partial

Note: Default for all tests is Target = SL flag, Action = 100, Pointer = 32 bits, Length = 96 bits, Mask

passed as directive parameter, Truncate

= Disable

Table 7. Select/Inventory Test Cases

Date: 2006-08-04 Version 1.2.4 Page 18 of 84

Interoperability Test System for EPC compliant Class-1 Gen-2 UHF RFID

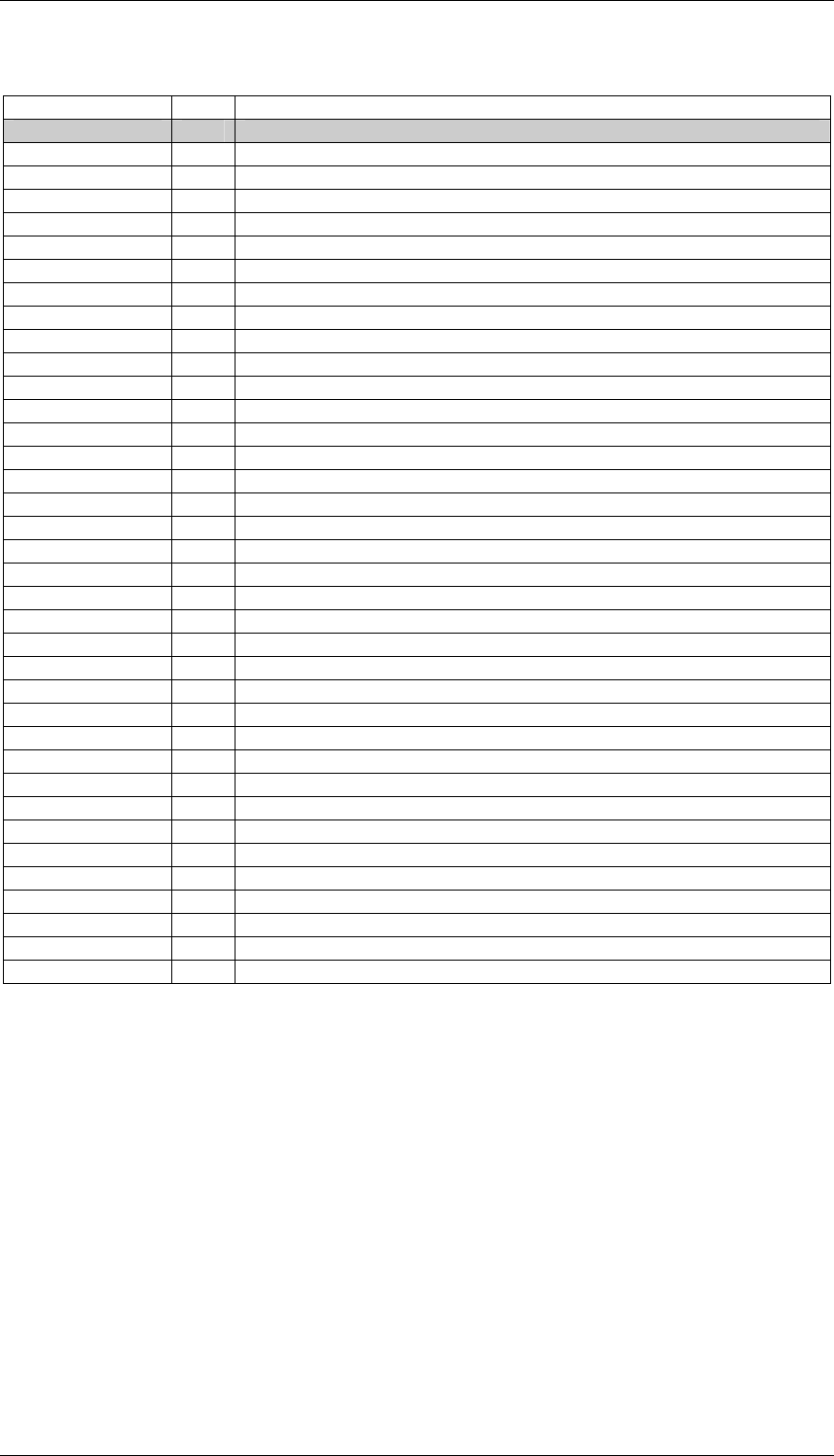

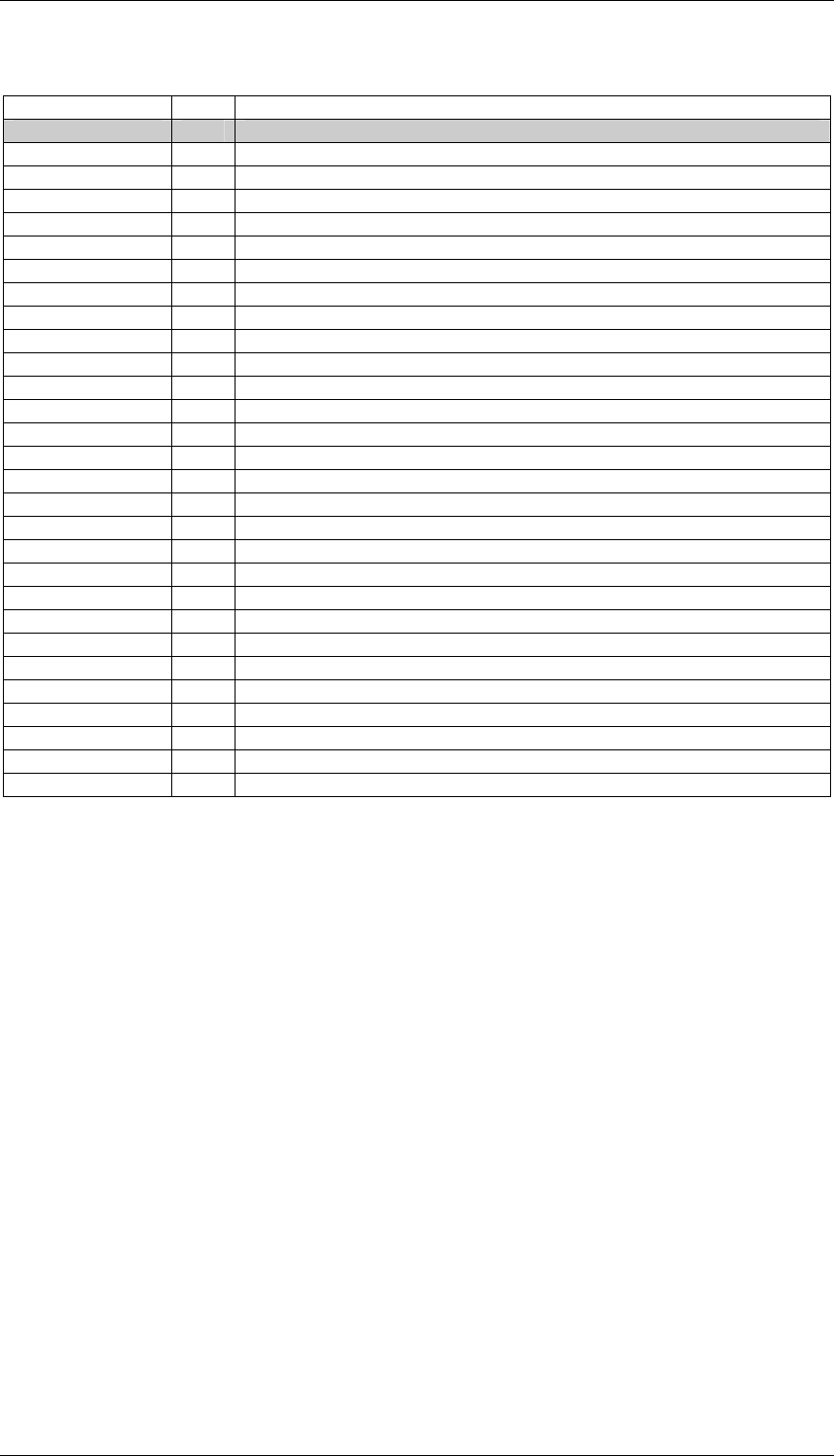

Select/Query

Test case Target Action Pointer Length Truncate Lock Memory

SQ_E_S0_1 S0 000 32 96 0 EPC

SQ_E_S0_2 S0 001 34 64 0 EPC

SQ_E_S0_3 S0 010 37 48 0 EPC

SQ_E_S0_4 S0 011 43 24 0 EPC

SQ_E_S0_5 S0 100 55 12 0 EPC

SQ_E_S0_6 S0 101 79 6 0 EPC

SQ_E_S0_7 S0 110 95 3 0 EPC

SQ_E_S0_8 S0 111 127 1 0 EPC

SQ_E_S1_1 S1 000 117 1 0 L EPC

SQ_E_S1_2 S1 001 97 3 0 L EPC

SQ_E_S1_3 S1 010 83 6 0 L EPC

SQ_E_S1_4 S1 011 64 12 0 L EPC

SQ_E_S1_5 S1 100 46 24 0 L EPC

SQ_E_S1_6 S1 101 42 48 0 L EPC

SQ_E_S1_7 S1 110 38 64 0 L EPC

SQ_E_S1_8 S1 111 32 96 0 L EPC

SQ_E_S2_1 S2 000 32 96 0 EPC

SQ_E_S2_2 S2 001 32 95 0 EPC

SQ_E_S2_3 S2 010 44 48 0 EPC

SQ_E_S2_4 S2 011 56 30 0 EPC

SQ_E_S2_5 S2 100 67 20 0 EPC

SQ_E_S2_6 S2 101 75 6 0 EPC

SQ_E_S2_7 S2 110 83 3 0 EPC

SQ_E_S2_8 S2 111 126 1 0 EPC

SQ_E_S3_1 S3 000 124 1 0 L EPC

SQ_E_S3_2 S3 001 102 3 0 L EPC

SQ_E_S3_3 S3 010 87 6 0 L EPC

SQ_E_S3_4 S3 011 59 12 0 L EPC

SQ_E_S3_5 S3 100 45 24 0 L EPC

SQ_E_S3_6 S3 101 41 48 0 L EPC

SQ_E_S3_7 S3 110 36 64 0 L EPC

SQ_E_S3_8 S3 111 32 96 0 L EPC

SQ_E_SL_1 SL 000 126 2 1 EPC

SQ_E_SL_2 SL 001 63 64 1 EPC

SQ_E_SL_3 SL 010 127 1 1 EPC

SQ_E_SL_4 SL 011 63 8 1 EPC

SQ_E_SL_5 SL 100 58 12 1 EPC

SQ_E_SL_6 SL 101 81 16 1 EPC

SQ_E_SL_7 SL 110 32 5 1 EPC

SQ_E_SL_8 SL 111 124 3 1 EPC

SQ_E_SL_9 SL 000 32 96 1 L EPC

SQ_E_SL_10 SL 001 32 95 1 L EPC

SQ_E_SL_11 SL 010 44 48 1 L EPC

SQ_E_SL_12 SL 011 56 30 1 L EPC

SQ_E_SL_13 SL 100 67 20 1 L EPC

SQ_E_SL_14 SL 101 75 6 1 L EPC

SQ_E_SL_15 SL 110 95 13 1 L EPC

SQ_E_SL_16 SL 111 126 1 1 L EPC

SQ_T_S0_1 S0 000 0 Half 0 TID

SQ_T_S0_2 S0 001 0 Full 0 TID

Date: 2006-08-04 Version 1.2.4 Page 19 of 84

Interoperability Test System for EPC compliant Class-1 Gen-2 UHF RFID

SQ_T_S1_1 S1 010 0 Half 0 L TID

SQ_T_S1_2 S1 011 0 Full 0 L TID

SQ_T_S2_1 S2 100 0 Half 0 TID

SQ_T_S2_2 S2 101 0 Full 0 TID

SQ_T_S3_1 S3 110 0 Half 0 L TID

SQ_T_S3_2 S3 111 0 Full 0 L TID

SQ_T_SL_1 SL 000 0 Half 0 TID

SQ_T_SL_2 SL 001 0 Full 0 TID

SQ_U_S0_1 S0 000 0 Half 0 User

SQ_U_S0_2 S0 001 0 Full 0 User

SQ_U_S1_1 S1 010 0 Half 0 L User

SQ_U_S1_2 S1 011 0 Full 0 L User

SQ_U_S2_1 S2 100 0 Half 0 User

SQ_U_S2_2 S2 101 0 Full 0 User

SQ_U_S3_1 S3 110 0 Half 0 User

SQ_U_S3_2 S3 111 0 Full 0 User

SQ_U_SL_1 SL 000 0 Half 0 L User

SQ_U_SL_2 SL 001 0 Full 0 L User

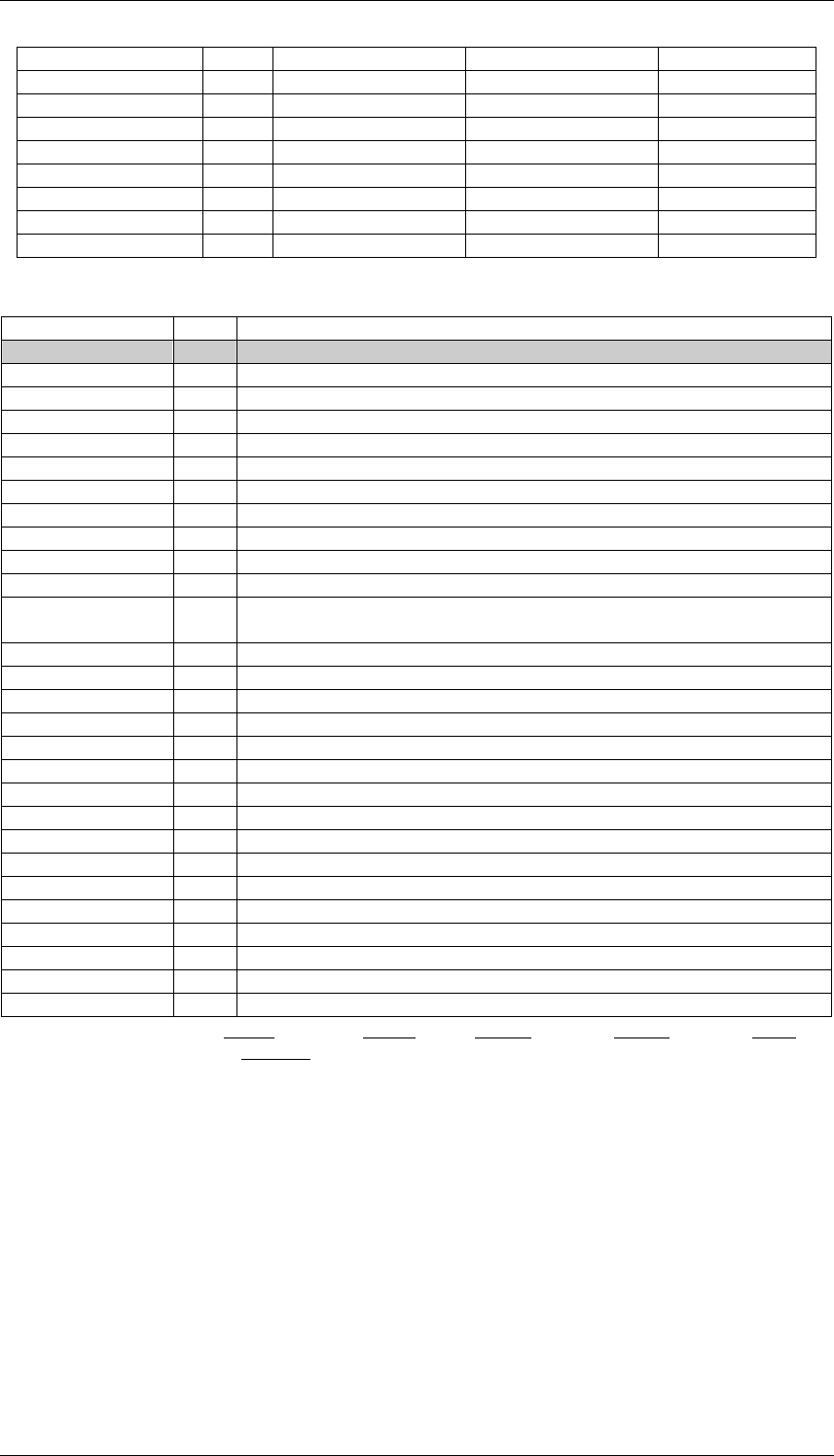

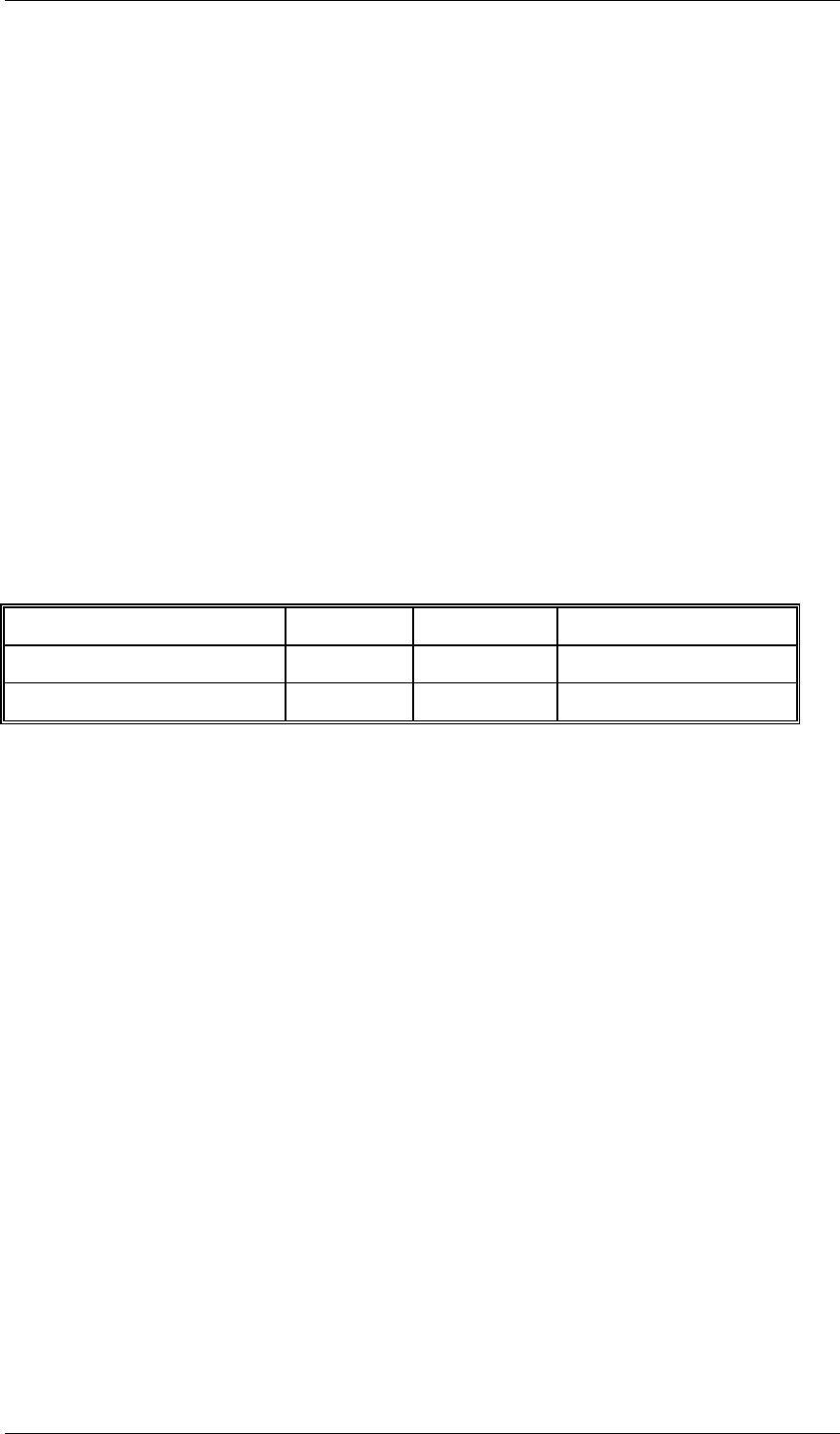

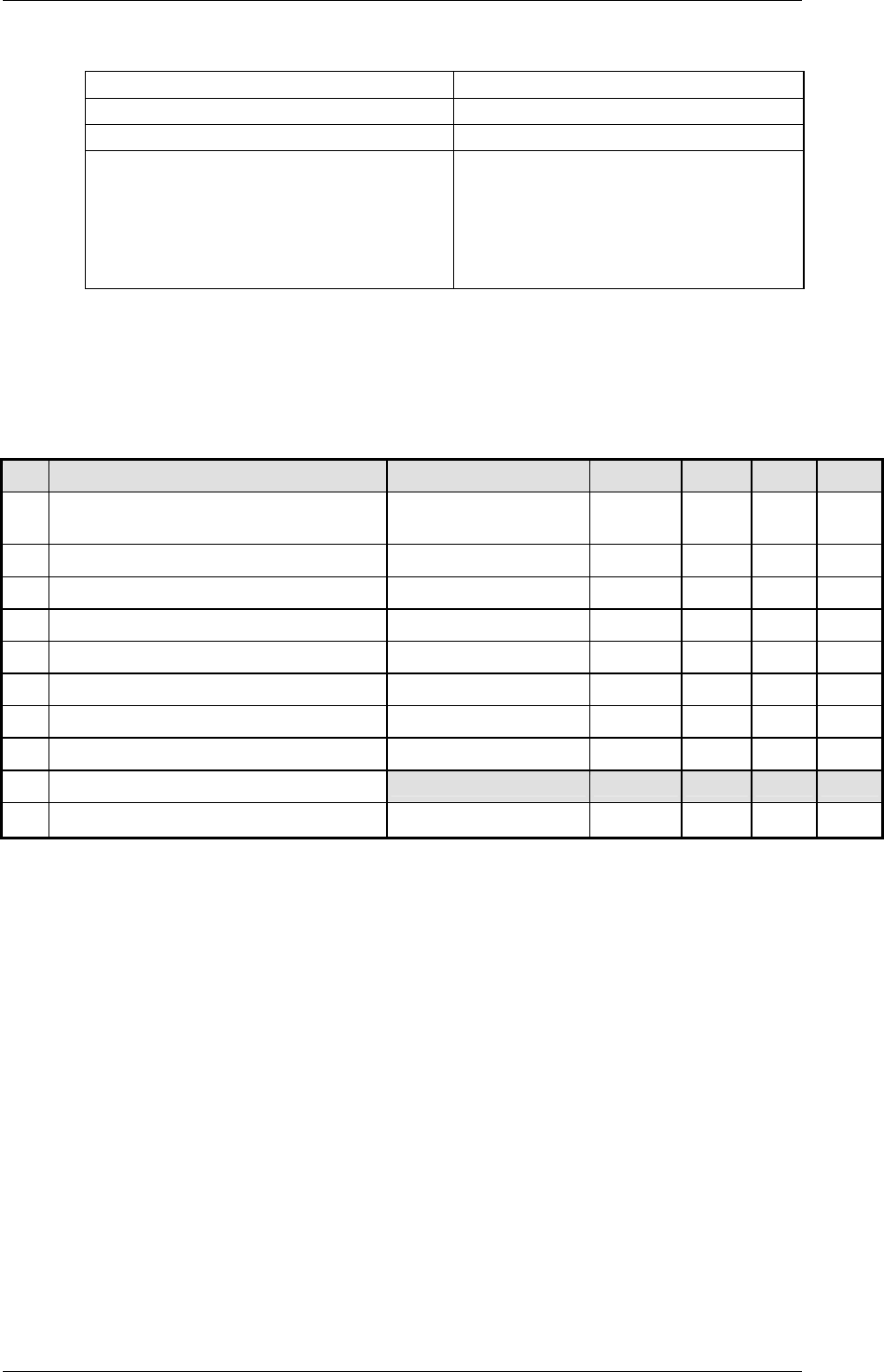

Table 8. Select/Query Test Cases

Note: All test cases use a single tag. Each test case corresponds to four Query/Inventory (Q=0) command

pairs as shown in the table below. For command pair 1, the Select mask is chosen to match the tag

memory contents and the Query parameters are chosen consistent with the Select matching action such

that the tag responds with its EPC. For command pair 2, the Query parameters are chosen to be

inconsistent with the Select matching action in such a way that the tag fails to respond with its EPC. For

command pair 3, the Select mask is chosen not to match the tag memory contents and the Query

parameters are chosen to be consistent with the Select non-matching action such that the tag responds

with its EPC. For command pair 4, the Query parameters are chosen to be inconsistent with the Select

non-matching actions in such a way that the tag fails to respond with its EPC. All four command pairs

must elicit the correct response for a test case to pass.

Command

Pair

Select Query action elicited

1 Match EPC returned

2 Match No EPC response

3 Mismatch EPC returned

4 Mismatch No EPC response

Table 9. Select/ Query Action

Date: 2006-08-04 Version 1.2.4 Page 20 of 84

Interoperability Test System for EPC compliant Class-1 Gen-2 UHF RFID

6.0 Scripting Language

6.1 Script Language Syntax

The Reader vendor should provide a PC application that runs a Script File and produces an

Output File. This application is invoked using the following syntax, where “interop” is the call

to the application and input file is the Script filename and output file is the Output filename.

interop <input file> <output file>

The input file (Script File) is a text file comprised of directives from a scripting language

described below. The Script File shall be read by the application and each line executed in

order. Results shall be written both to the screen and to the output file (Output File) for

documentation and as inputs to the Software Manager for parsing and report generation.

Examples of a Script and Output File are provided in section 7.2 and 7.3.

The scripting language is intended to be as simple as possible, both for the operator (in terms of

being able to create powerful tests using simple building blocks) and for the application (in

terms of being able to parse and understand the directives). The scripting language is line-

oriented, meaning that individual directives within the testing language are separated by

carriage returns. Blank lines are allowed and cause no actions to occur. Comments are indicated

by a leading '#' character with the characters that follow having no operational influence. The

comment character can occur anywhere on the line. Examples:

# This is a line with nothing but a comment

Disconnect # This is a comment coming after a sample directive

It is advised to use informative comments when creating the testing scripts. All comments,

blank lines, and directives are echoed to the output file.

The result of each directive is printed to the screen and the output file whose name is specified.

Each directive can individually either succeed or fail. For example, a write command may fail

due to the memory being locked. Another means of failure is a mismatch with an expected data

result. The application shall indicate failure for any directive where the actual pass/fail result

mismatches the expectation. All directives must match their expected result for overall success

to be declared for a Script File. The application shall declare "SUCCESS" at the end of the

Output File if all directives matched expectation. "FAILURE" is declared if any one directive

had an unexpected result.

The core functionality of the testing language comes from its interpretation of a number of test

directives. The list of supported directives and their syntax is shown below. If the application

encounters an out of order or unrecognisable directive (lack of necessary arguments, presence of

invalid arguments, attempting to perform RFID operations before connecting to a reader, etc.),

then the directive is ignored and a diagnostic message describing the error is printed to the

screen and output file. The following is the full list of supported directives. Parameters in <..>

are mandatory, those in [..] are optional.

Inventory <expect> <n> [mask] [location]

Description:

This directive attempts to inventory tags that are in the field of view of the reader using

repetitive inventory rounds. The option exists to select a sub-population of tags prior to

inventory. Selection occurs based on an optional mask parameter field. This directive

will succeed if the reader is able to inventory n tags where the value n is specified as a

parameter; and will fail otherwise.

Date: 2006-08-04 Version 1.2.4 Page 21 of 84

Interoperability Test System for EPC compliant Class-1 Gen-2 UHF RFID

Parameters:

expect

Must be equal to "pass" or "fail", depending upon whether this directive is expected to

succeed or not.

n

The number of unique EPCs that are expected to be found by the reader. If, for example,

10 tags are in the field of view of the reader and an inventory directive is executed

without selection, then 10 tags should be found and the directive will pass if n=10 was

specified. If a sub-population is targeted using the mask option, then a lower n value

may be specified even though 10 total tags are in the field of view.

mask

A hexadecimal string that the EPC must match for the select criteria to apply. String

corresponds to a Select mask starting at the EPC MSB. If not specified, default is no

Select mask, that is, complete population is inventoried.

location

Use "epc" for the EPC memory bank, "tid" for the TID memory bank, and "user" for the

user memory bank. If not specified, default is epc.

Examples:

Inventory pass 1

Inventory fail 3 F3C5 user

Result:

Inventoried <count> unique tags.

The count is the number of unique EPCs found.

EPC result: <epc_value> <:count> (see following example)

30035A0001B4F449A720CD20 :33

30035A0001B4F449A720CD21 :30

30035A0001B4F449A720CD22 :25

A hexadecimal list of EPCs found followed by the decimal number of times each was

inventoried.

Inventory <result>.

The result is "SUCCESSFUL" if the directive matched the expectation, or "FAILED" if

the directive mismatched the expectation. The number of unique tags found is compared

to the number of expected tags to determine success/failure.

Read <expect> <data> <location>[,<offset>,<length>] [password]

Description:

This directive attempts to read a particular memory location in the tag under test. The

memory bank is specified in the location field. Optional offset and length parameters

specify the start and length of data to read if a partial memory read is desired. If this

field is omitted, the complete memory will be read. The data field contains the data

expected to be return from the read. A dash in this field eliminates the requirement for a

match with expected data to achieve success. The password field is used if a password

is required to perform the operation. If the password is omitted, memory access will be

attempted from the open state. This directive will succeed if the data can be read and it

matches the expected data; and will fail otherwise.

Parameters:

expect

Must be equal to "pass" or "fail", depending upon whether this directive is expected to

succeed or not.

data

Date: 2006-08-04 Version 1.2.4 Page 22 of 84

Interoperability Test System for EPC compliant Class-1 Gen-2 UHF RFID

A hexadecimal string that the read data will be matched against, or "-" to indicate that

no matching should be performed.

location

Use "kpass" for the kill password, "apass" for the access password, "epc" for the EPC

memory bank, "tid" for the TID memory bank, and "user" for the user memory bank.

offset

Decimal word offset (word is 16 bits) to start of data to written. If omitted, the starting

location of the memory bank is used.

length

Decimal word length to read. If omitted, the all the words in the memory bank are read.

password

A hexadecimal string that will be used by the reader to perform a tag access from the

secured state. If the password is omitted the tag access is performed from the open state.

Examples:

Read pass - tid

Read fail 1111 kpass,1,1 33334444

Result:

Read data: <data>

The data is a hexadecimal string of the data that was read from tag memory, or "" if no

data could be read.

Read <result>.

The result is "SUCCESSFUL" if the directive matched the expectation, or "FAILED" if

the directive mismatched the expectation. If data is specified it is compared to the read

result to determine success/failure.

Write <expect> <data> <location>[,<offset>] [password]

Description:

This directive attempts to write a particular memory location in the tag under test. The

memory bank is specified in the location field. An optional offset parameter specifies

the starting position in the bank to write if a partial memory write is desired. If this field

is omitted, the complete memory will be written. The data field contains the data to be

written. The password field is used if a password is required to perform the operation. If

the password is omitted, memory access will be attempted from the open state. This

directive will succeed if the tag reports a successful write and the read results matches

data if data is specified; and will fail otherwise.

Parameters:

expect

Must be equal to "pass" or "fail", depending upon whether this directive is expected to

succeed or not.

data

A hexadecimal string that represents the data to be written. If it is shorter than the length

of remaining memory then the higher-numbered rows will be left unmodified.

location

Use "kpass" for the kill password, "apass" for the access password, "epc" for the EPC

memory bank, "tid" for the TID memory bank, and "user" for the user memory bank.

offset

Decimal word offset (word is 16 bits) to start of data to written. If omitted, the starting

location of the memory bank is used.

password

A hexadecimal string that will be used by the reader to perform a tag access from the

secured state. If the password is omitted the tag access is performed from the open state.

Date: 2006-08-04 Version 1.2.4 Page 23 of 84

Interoperability Test System for EPC compliant Class-1 Gen-2 UHF RFID

Examples:

Write pass 11112222 kpass

Write fail 1111 tid,1 33334444

Result:

Write result: <data>

The data is "1" if the write operation was successful, or "0" if it was not successful.

Write <result>.

The result is "SUCCESSFUL" if the directive matched the expectation, or "FAILED" if

the directive mismatched the expectation.

WrRd <expect> <data> <location>[,<offset>] [password]

Description:

This directive attempts to write a particular memory location of the tag under test then

read the same location to verify a successful write. The memory bank is specified in the

location field. An optional offset parameter specifies the starting position in the bank to

write if a partial memory write is desired. If this field is omitted, the complete memory

will be written. The data field contains the data to be written. The password field is used

if a password is required to perform the operation. If the password is omitted, memory

access will be attempted from the open state. This directive will succeed if the tag

reports a successful write and the read data matches what was written; and will fail

otherwise.

Parameters:

expect

Must be equal to "pass" or "fail", depending upon whether this directive is expected to

succeed or not.

data

A hexadecimal string that represents the data to be written. If it is shorter than the length

of remaining memory then the higher-numbered rows will be left unmodified.

location

Use "kpass" for the kill password, "apass" for the access password, "epc" for the EPC

memory bank, "tid" for the TID memory bank, and "user" for the user memory bank.

offset

Decimal word offset (word is 16 bits) to start of data to written. If omitted, the starting

location of the memory bank is used.

password

A hexadecimal string that will be used by the reader to perform a tag access from the

secured state. If the password is omitted the tag access is performed from the open state.

Examples:

WrRd pass 11112222 kpass

WrRd fail 1111 tid,1 33334444

Result:

WrRd write result: <data>

The data is "1" if the write operation was successful, or "0" if it was not successful.

WrRd read result: <data>

The data is a hexadecimal string of the data that was read from tag memory, or "" if no

data could be read. Note that this statement is omitted if the read operation is not done.

This happens when the write operation mismatches the directive expectation.

WrRd <result>

Date: 2006-08-04 Version 1.2.4 Page 24 of 84

Interoperability Test System for EPC compliant Class-1 Gen-2 UHF RFID

The result is "SUCCESSFUL" if the directive matched the expectation, or "FAILED" if

the directive mismatched the expectation. Data is compared to the read result to

determine success/failure.

Lock <expect> <location> [password]

UnLock <expect> <location> [password]

PermLock <expect> <location> [password]

PermUnLock <expect> <location> [password]

Description:

All four of these directives are used to change the lock state of the tag under test. These

directives set and clear the lock bit, and they set the permalock bit in the location field

of Table 6.40 in Gen 2 protocol specification. For example, if the tag memory is in the

unlocked state (lock and permalock bits both zero) a PermLock directive will set the

permalock bit to one and put the memory in a perma-unlocked state. Likewise, the tag

memory must set the lock bit by issuing a Lock directive either prior or post to issuing a

PermLock directive to put the tag memory in a permalock state. The PermUnLock

directive attempts to deassert the permalock bit. The password field is used if an access

password is required to perform the operation. If the password is omitted, memory

access will be attempted from the open state. This directive will succeed if the tag

reports a successful lock or unlock; and will fail otherwise.

Parameters:

expect

Must be equal to "pass" or "fail", depending upon whether this directive is expected to

succeed or not.

location

Use "kpass" for the kill password, "apass" for the access password, "epc" for the EPC

memory bank, "tid" for the TID memory bank, and "user" for the user memory bank.

password

A hexadecimal string that will be used by the reader to perform a tag access from the

secured state. If the password is omitted the tag access is performed from the open state.

Examples:

Lock pass user 33334444

UnLock fail epc

PermLock fail user

PermUnLock pass epc 33334444

Result:

Lock result: <data>

UnLock result: <data>

PermLock result: <data>

PermUnLock result: <data>

The data is "1" if the lock operation was successful, or "0" if it was not successful.

Lock <result>.

UnLock <result>.

PermLock <result>.

PermUnLock <result>.

The result is "SUCCESSFUL" if the directive matched the expectation, or "FAILED" if

the directive mismatched the expectation.

Kill <expect> <kpassword>

Date: 2006-08-04 Version 1.2.4 Page 25 of 84

Interoperability Test System for EPC compliant Class-1 Gen-2 UHF RFID

Description:

This directive attempts to kill the tag under test using the kill password specified in the

password field. The directive succeeds if the tag reports a successful kill operation; and

will fail otherwise.

Date: 2006-08-04 Version 1.2.4 Page 26 of 84

Interoperability Test System for EPC compliant Class-1 Gen-2 UHF RFID

Parameters:

expect

Must be equal to "pass" or "fail", depending upon whether this directive is expected to

succeed or not.

kpassword

A hexadecimal string that specifies the kill password to be used for the kill operation.

Examples:

Kill pass FFFFFFFF

Result:

Kill result: <data>

The data is "1" if the kill operation was successful, or "0" if it was not successful.

Kill <result>.

The result is "SUCCESSFUL" if the directive matched the expectation, or "FAILED" if

the directive mismatched the expectation.

SQ <expect> <location> <epclength> <starget> <action> <pointer> <length> <mask>

<truncate> <session> <sel> <qtarget>

Description:

The Select/Query directive causes the reader to send a Select command followed

immediately by a Query command to the tag. The parameter list contains many of the

Select and Query parameters specified in the Gen 2 protocol specification. Parameters

that are not included are determined by the reader mode which is set in the

configuration directive. The Q value parameter in the Query command shall be

defaulted to zero to assure an immediate response from the single tag that is being

interrogated.

Parameters:

expect

Must be equal to "pass" or "fail", depending upon whether this directive is expected to

succeed or not. Pass should be specified when a valid EPC is expected to be returned by

the tag.

location

Use "epc" for the EPC memory bank, "tid" for the TID memory bank, and "user" for the

user memory bank.

epclength

Decimal integer indicating the number of EPC bits supported by the tag-under-test. A

typical value is 96 bits.

starget

The Select target parameter specifies which flag to modify if the select mask matches

the tag memory value. Use "s0" for the inventoried S0 flag, "s1" for the inventoried S1

flag, "s2" for the inventoried S2 flag, "s3" for the inventoried S3 flag, and "sl" for the

SL flag.

action

Action is a three digit binary number as defined in Table 6.19 of the Gen 2 protocol

specification that defines the action the targeted flag takes when the mask matches and

mismatches the value in the tag memory.

pointer

Decimal integer that specifies the memory offset at which the select mask is applied.

The pointer is not

in the extensible bit vector format used in the Gen 2 Select command.

length

Date: 2006-08-04 Version 1.2.4 Page 27 of 84

Interoperability Test System for EPC compliant Class-1 Gen-2 UHF RFID

Decimal integer that specifies the length of the select mask in bits, with the length being

left justified for selecting the portion of the mask. For mask lengths that are not

multiples of 4, the mask used will be padded with zeros for its remainder least

significant bits. For example, if the mask is 7F, and the length is 7, the mask used will

be 7E.

mask

A hexadecimal string indicating the bit pattern to be compared with the tag memory for

purposes of selecting a sub-population of tags. If the mask length is not a multiple of

four then the mask will be left justified with trailing zeros in the unused LSB’s.

truncate

Use “1” to enable a truncated reply from tag and “0” for an un-truncated response.

session

The Query session parameter specifies which flag to use for inventorying. Use "s0" for

the S0 flag, "s1" for the S1 flag, "s2" for the S2 flag, and "s3" for the S3 flag.

sel

A two digit binary number specifying the whether selected, unselected or all tags

respond to a Query. See Table 6.20 in Gen 2 protocol specification for details.

qtarget

The Query target parameter. Use “A” to choose tags in A state to participate in

inventory and “B” to choose B state tags for participation.

Examples:

SQ pass epc sl 000 45 30 B345FE14 0 s0 00 A

SQ fail user s0 000 32 64 123AB45FA125BC12 0 s0 00 B

Result:

SQ result: <data>

The data is "1" if the tag responded with a valid EPC value, or "0" if there was no tag

response.

EPC result: <epc_value> (see following example)

30035A0001B4F449A720CD22

The returned EPC if data=1; no output if data=0

SQ <result>.

The result is "SUCCESSFUL" if the directive matched the expectation, or "FAILED" if

the directive mismatched the expectation.

Connect <address> <domain> <mode>

Description:

This directive attempts to connect to the reader. The directive should be used before

attempting any testing directives, and should not be used when already connected to a

reader. The target reader is specified by the address parameter. The domain and mode

parameters specify configuration information for that reader.

Parameters:

address

The address of the reader to connect to. This can either be an IP address or, if DNS

resolution is available, the name of the reader.

domain

Use "FCC" for connecting to a reader operating within the FCC domain, and "ETSI" for

connecting to a reader operating within the ETSI domain.

mode

An positive integer mode number that uniquely specifies the modulation type, Tari, PIE,

LF, M, DR, and TRext used by the reader and commanded of the tag.

Date: 2006-08-04 Version 1.2.4 Page 28 of 84

Interoperability Test System for EPC compliant Class-1 Gen-2 UHF RFID

Examples:

Connect speedway0111 FCC 2

Connect 192.168.10.51 ETSI 0

Disconnect

Description:

This directive attempts to disconnect a connected reader. The directive should be used

for reconnecting to a different reader in the midst of a test. It is not necessary to issue

this directive at the end of the test.

Parameters:

Example:

Disconnect

Power <power>

Description:

This directive attempts to set the reader transmit power level as measured at the RF

connector.

Parameters:

power

A floating-point value in the range between 15.0 and 30.0, inclusive. Units are dBm.

The reader shall set the power level as closely as possible to the commanded value.

Example:

Power 15.0

Antenna <m>

Description:

This directive is used to select the active transmit antenna port. Only one transmit

antenna port shall be active at a time during any interoperability testing.

Parameters:

m

An integer greater than or equal to 1.

Example:

Antenna 2

Frequency <frequency>

Description:

This directive attempts to set the operating frequency to be used by the reader. This

directive applies only to readers designed for operation in a region allowing fixed

frequency operation.

Parameters:

frequency

A floating-point value in the range between Fmin and Fmax representing the minimum

and maximum channel frequencies for the particular regulatory region. Units are MHz.

For ETSI the values are 865.7 and 867.5.

Example:

Date: 2006-08-04 Version 1.2.4 Page 29 of 84

Interoperability Test System for EPC compliant Class-1 Gen-2 UHF RFID

Frequency 866.3

Date: 2006-08-04 Version 1.2.4 Page 30 of 84

Interoperability Test System for EPC compliant Class-1 Gen-2 UHF RFID

6.2 Script File Example

The following Script File illustrates the use of a commented string of directives to test secured

access of tag memory.

Connect speedway0022 FCC 2

# Read kill and access passwords.

Read pass - kpass

Read pass - apass

# Test partial writing of kill password.

WrRd pass 00000000 kpass

WrRd pass FFFF kpass,1

Read pass 0000FFFF kpass

# Write kill and access passwords.

WrRd pass AAAAAAAA kpass

WrRd pass BBBBBBBB apass

# Lock kill and access passwords.

Lock pass kpass BBBBBBBB

Lock pass apass BBBBBBBB

# Read kill and access passwords.

Read pass AAAAAAAA kpass BBBBBBBB

Read pass BBBBBBBB apass BBBBBBBB

# Fail to kill tag with wrong password.

Kill fail 11111111

# Unlock kill and access passwords.

UnLock pass kpass BBBBBBBB

UnLock pass apass BBBBBBBB

# Read EPC.

Read pass - epc

# Write EPC.

WrRd pass 1234567890ABCDEF12345678 epc

# Lock EPC

Lock pass epc BBBBBBBB

# Write EPC.

WrRd pass 111122223333444455556666 epc BBBBBBBB

# Unlock EPC.

UnLock pass epc BBBBBBBB

# Reset kill and access passwords.

WrRd pass 00000000 kpass

WrRd pass 00000000 apass

Disconnect

6.3 Output File Example

The following Output file shows the output from the Script File example from 6.2.

Connect speedway0022 FCC 2

Connected to reader speedway0022, type 0, mode 2.

# Read kill and access passwords.

Read pass - kpass

Read data: 00000000

Read SUCCESSFUL.

Date: 2006-08-04 Version 1.2.4 Page 31 of 84

Interoperability Test System for EPC compliant Class-1 Gen-2 UHF RFID

Read pass - apass

Read data: 00000000

Read SUCCESSFUL.

# Test partial writing of kill password.

WrRd pass 00000000 kpass

WrRd write result: 1

WrRd read result: 00000000

WrRd SUCCESSFUL.

WrRd pass FFFF kpass,1

WrRd write result: 1

WrRd read result: FFFF

WrRd SUCCESSFUL.

Read pass 0000FFFF kpass

Read data: 0000FFFF

Read SUCCESSFUL.

# Write kill and access passwords.

WrRd pass AAAAAAAA kpass

WrRd write result: 1

WrRd read result: AAAAAAAA

WrRd SUCCESSFUL.

WrRd pass BBBBBBBB apass

WrRd write result: 1

WrRd read result: BBBBBBBB

WrRd SUCCESSFUL.

# Lock kill and access passwords.

Lock pass kpass BBBBBBBB

Lock result: 1

Lock SUCCESSFUL.

Lock pass apass BBBBBBBB

Lock result: 1

Lock SUCCESSFUL.

# Read kill and access passwords.

Read pass AAAAAAAA kpass BBBBBBBB

Read data: AAAAAAAA

Read SUCCESSFUL.

Read pass BBBBBBBB apass BBBBBBBB

Read data: BBBBBBBB

Read SUCCESSFUL.

# Fail to kill tag with wrong password.

Kill fail 11111111

Kill result: 0

Kill SUCCESSFUL.

# Unlock kill and access passwords.

UnLock pass kpass BBBBBBBB

UnLock result: 1

UnLock SUCCESSFUL.

UnLock pass apass BBBBBBBB

UnLock result: 1

UnLock SUCCESSFUL.

# Read EPC.

Read pass - epc

Read data: 1111222233334444555566660000

Read SUCCESSFUL.

# Write EPC.

WrRd pass 1234567890ABCDEF12345678 epc

WrRd write result: 1

WrRd read result: 1234567890ABCDEF12345678

WrRd SUCCESSFUL.

Date: 2006-08-04 Version 1.2.4 Page 32 of 84

Interoperability Test System for EPC compliant Class-1 Gen-2 UHF RFID

# Lock EPC

Lock pass epc BBBBBBBB

Lock result: 1

Lock SUCCESSFUL.

# Write EPC.

WrRd pass 111122223333444455556666 epc BBBBBBBB

WrRd write result: 1

WrRd read result: 111122223333444455556666

WrRd SUCCESSFUL.

# Unlock EPC.

UnLock pass epc BBBBBBBB

UnLock result: 1

UnLock SUCCESSFUL.

# Reset kill and access passwords.

WrRd pass 00000000 kpass

WrRd write result: 1

WrRd read result: 00000000

WrRd SUCCESSFUL.

WrRd pass 00000000 apass

WrRd write result: 1

WrRd read result: 00000000

WrRd SUCCESSFUL.

Disconnect

Disconnected.

OVERALL RESULT: SUCCESS

Date: 2006-08-04 Version 1.2.4 Page 33 of 84

Interoperability Test System for EPC compliant Class-1 Gen-2 UHF RFID

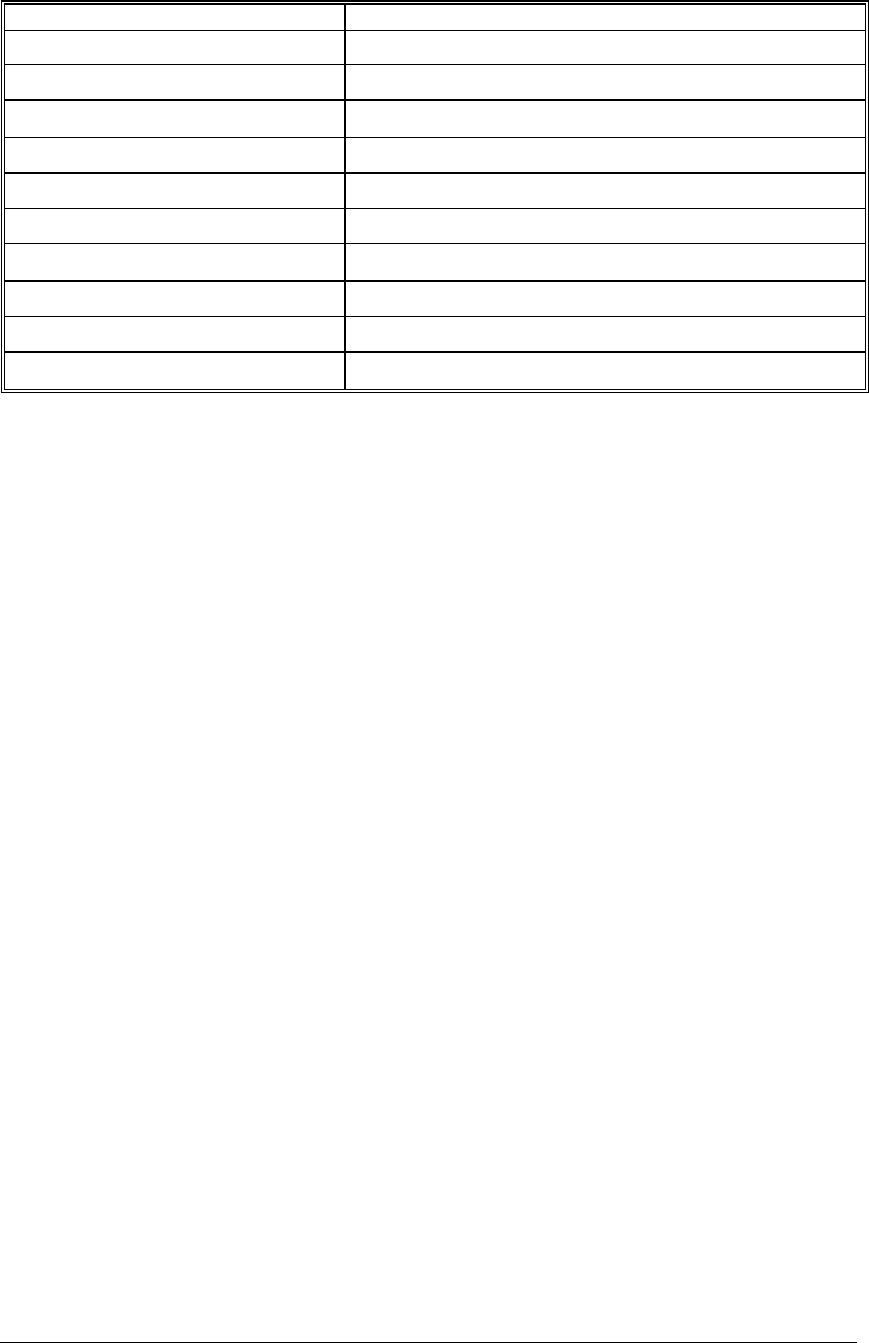

7.0 Test Sites

This section introduces general characteristics of three test sites used to test the test cases

defined in this document.

7.1 General Characteristics

The characteristics here described apply to all test cases detailed in the following sections:

- The test site shall be on a reasonably flat surface or ground.

- For inventory and access operations, the distance between the reader and tag shall be

as specified by the tag manufacturer for the particular RFID application under

evaluation. Reader transmit power shall be sufficient to provide the specified power to

the tag over that range. In the case of a mixed population of tags, the distance will be

set to the minimum tag distance requirement. Note that the distance requirement may

be different for inventory, read, write, lock, and kill operations. To facilitate

continuous testing via script, the minimum distance across all operations may be used

for all tests

The next items describe general statements concerning the interrogator placement in all test

sites:

- Interrogator shall be at fixed and stationary position.

- The interrogator antenna shall be placed vertical on a non-conducting support.

- The height of the interrogator antenna shall ensure the correct operation of the entire

interrogator.

- If the interrogator can use two or more antennas simultaneously, just one antenna shall

be operating and connected to the interrogator.

- For ensuring an interference free environment, no other devices or interrogators shall

be operating, at the same frequency range as the SUT, inside the test site area.

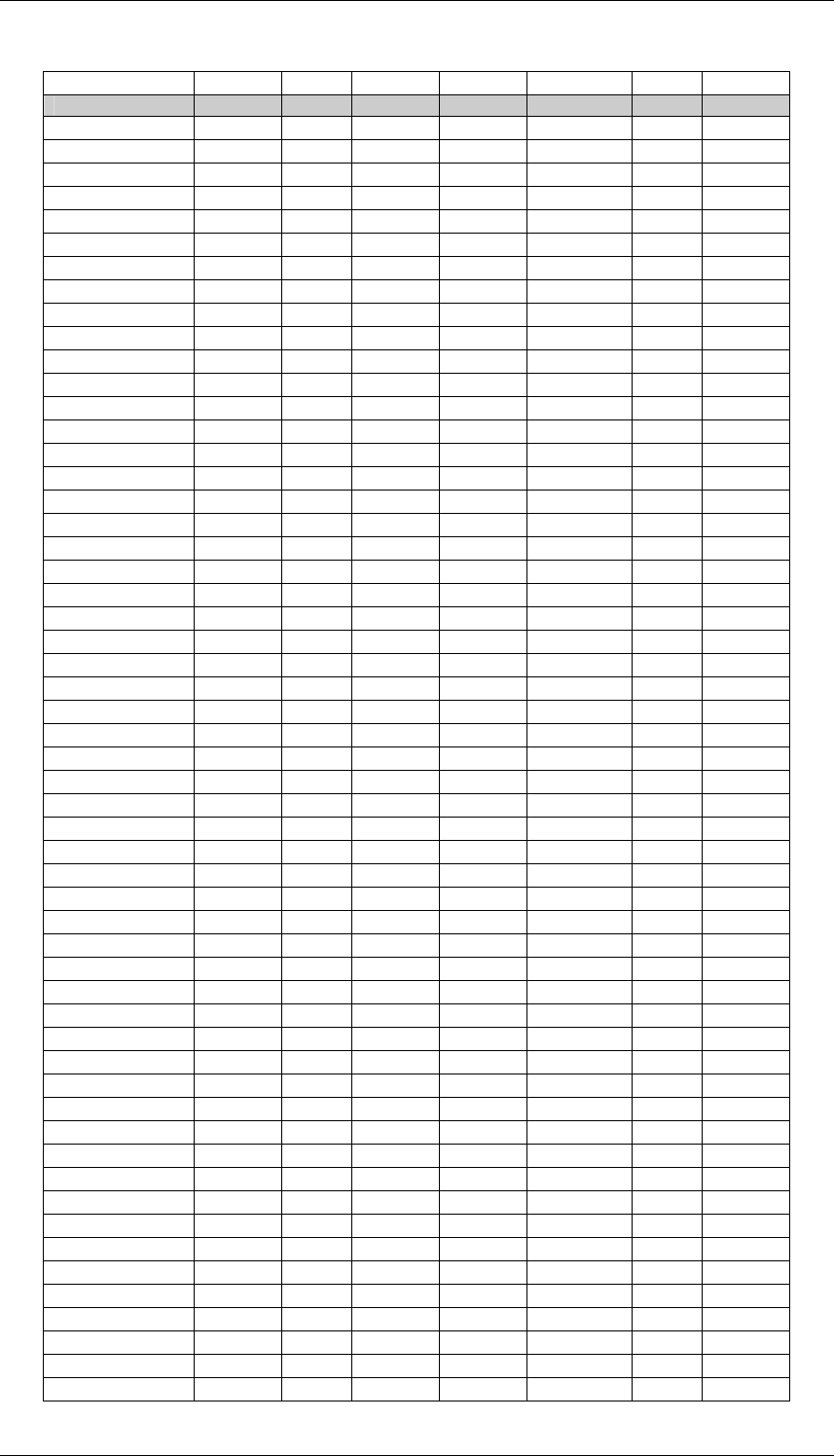

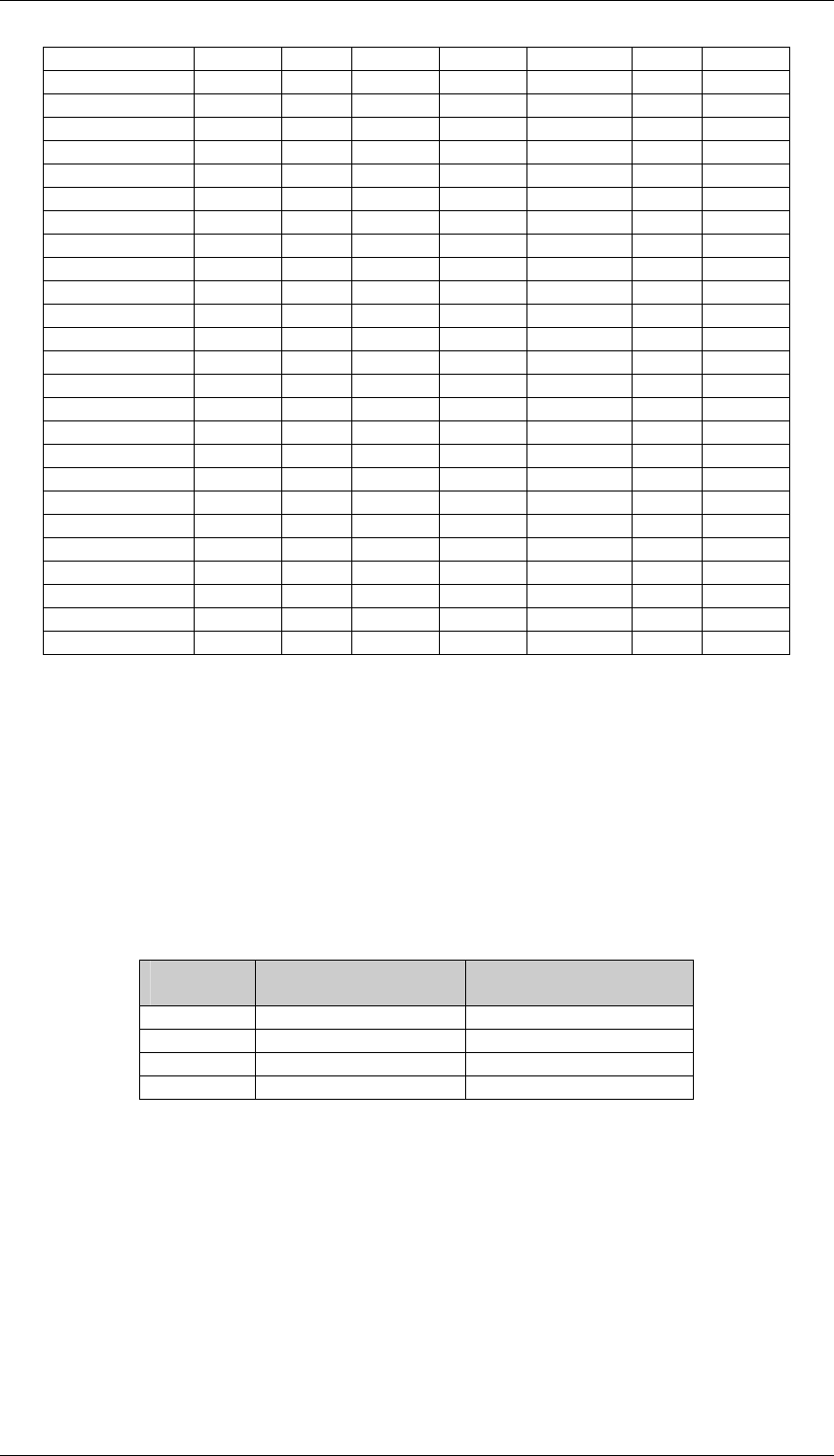

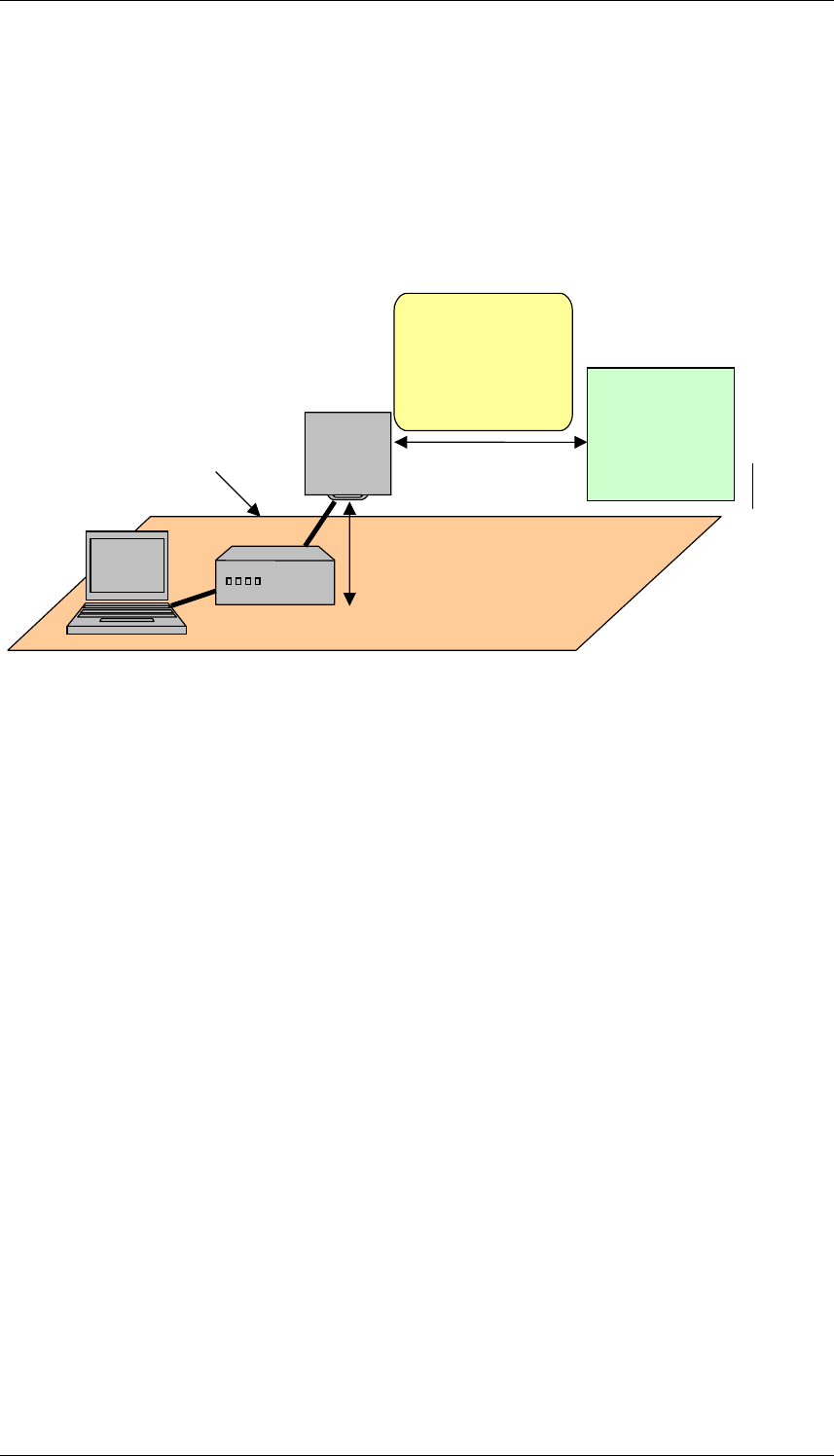

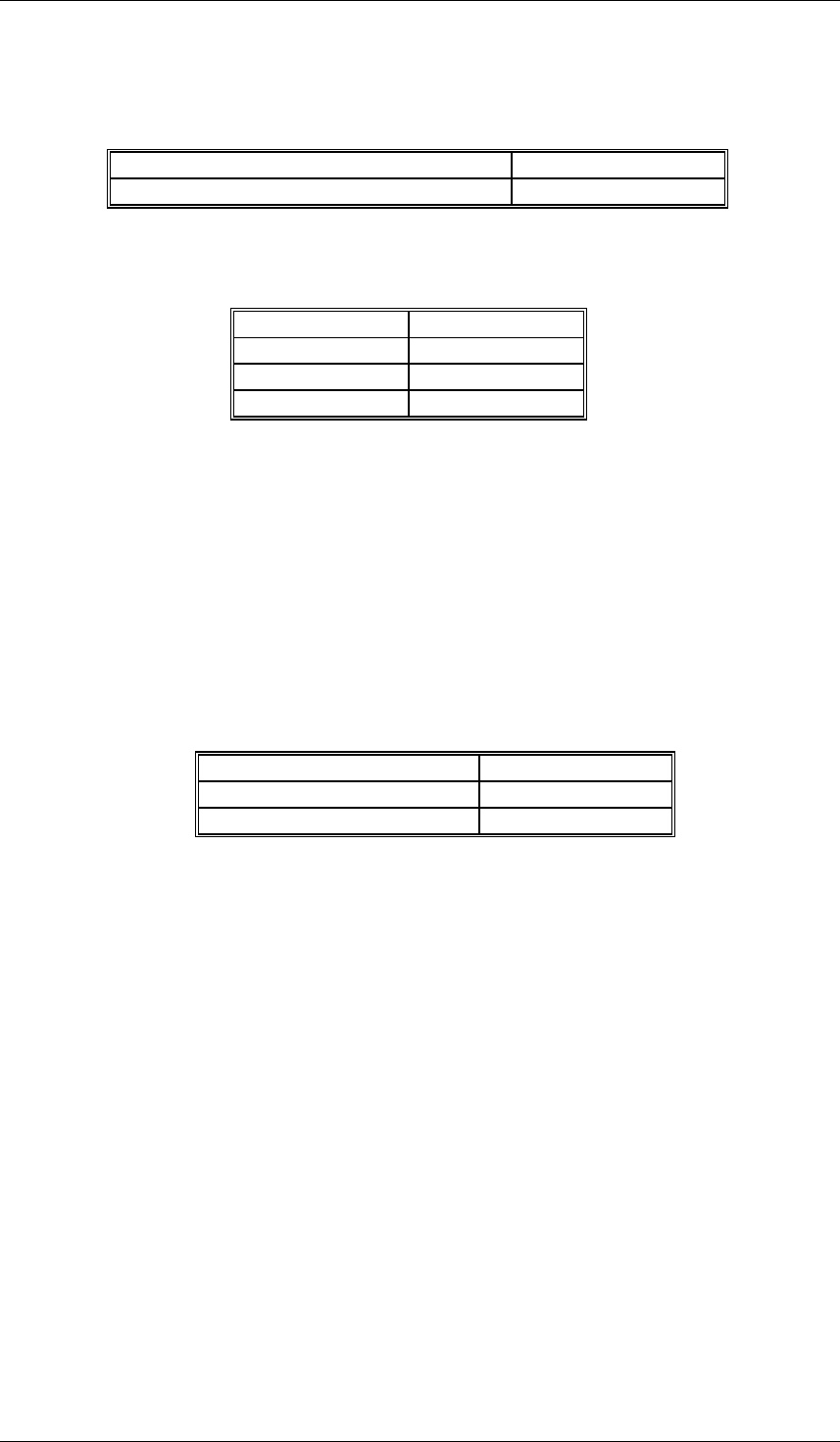

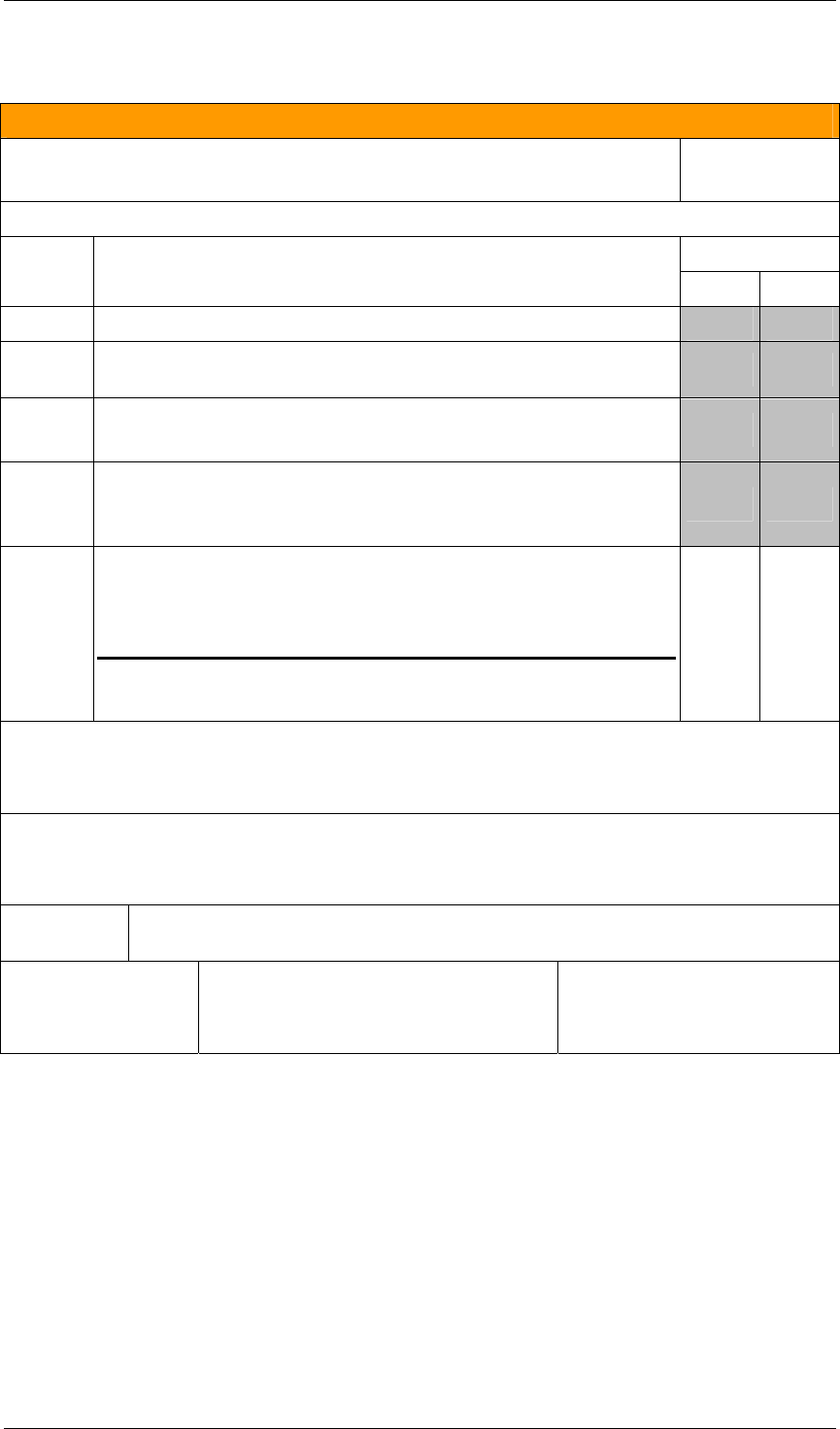

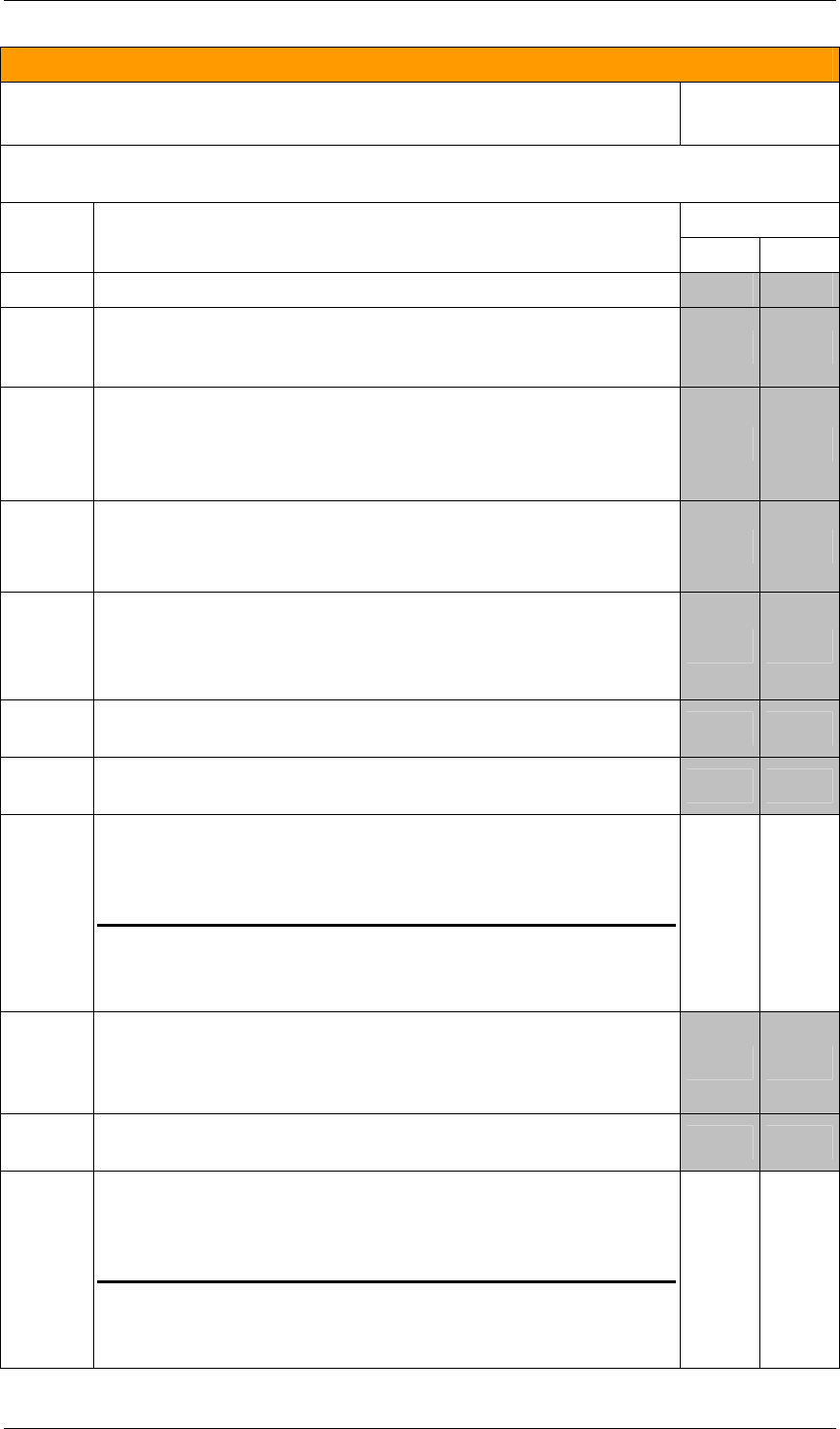

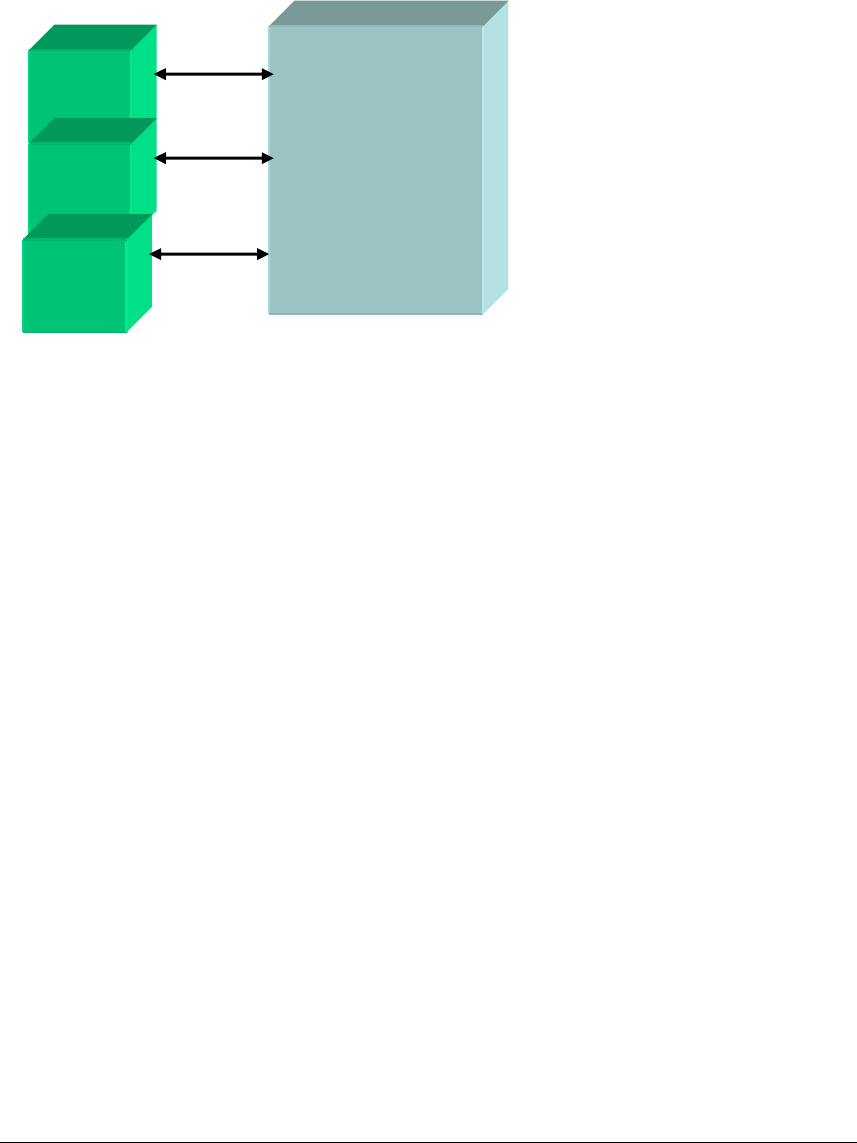

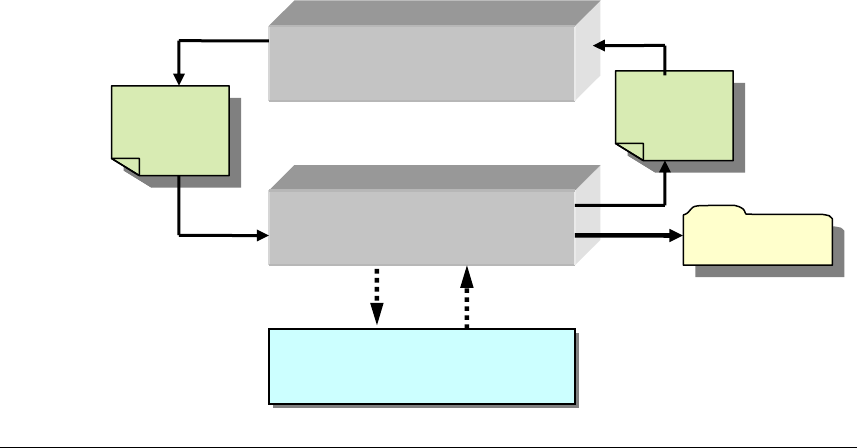

7.2 Multiple-tag Setup

The multiple-tag setup may be a flat surface of a non-conducting material with maximum area

of 1 m x 1 m. The multiple-tag setup contains a group of tags from the same (homogeneous) or

different (mixed) label or inlay manufacturers. This tags shall contain a class 1 Gen 2 IC. The

tags shall be evenly distributed and maintain a separation between them of not less than 10 cm.

The maximum number of tags in the setup shall be 25. Figure 6 depicts the multiple-tag setup.

Date: 2006-08-04 Version 1.2.4 Page 34 of 84

Interoperability Test System for EPC compliant Class-1 Gen-2 UHF RFID

3

3

3

3

3

3

3

3

3

3

g

Non

-

conductin

surface

3

3

3

3

3

3

3

3

3

3

3

3

3

10 cm

3

3

1 m

1 m

Figure 1. Multi-tag Board

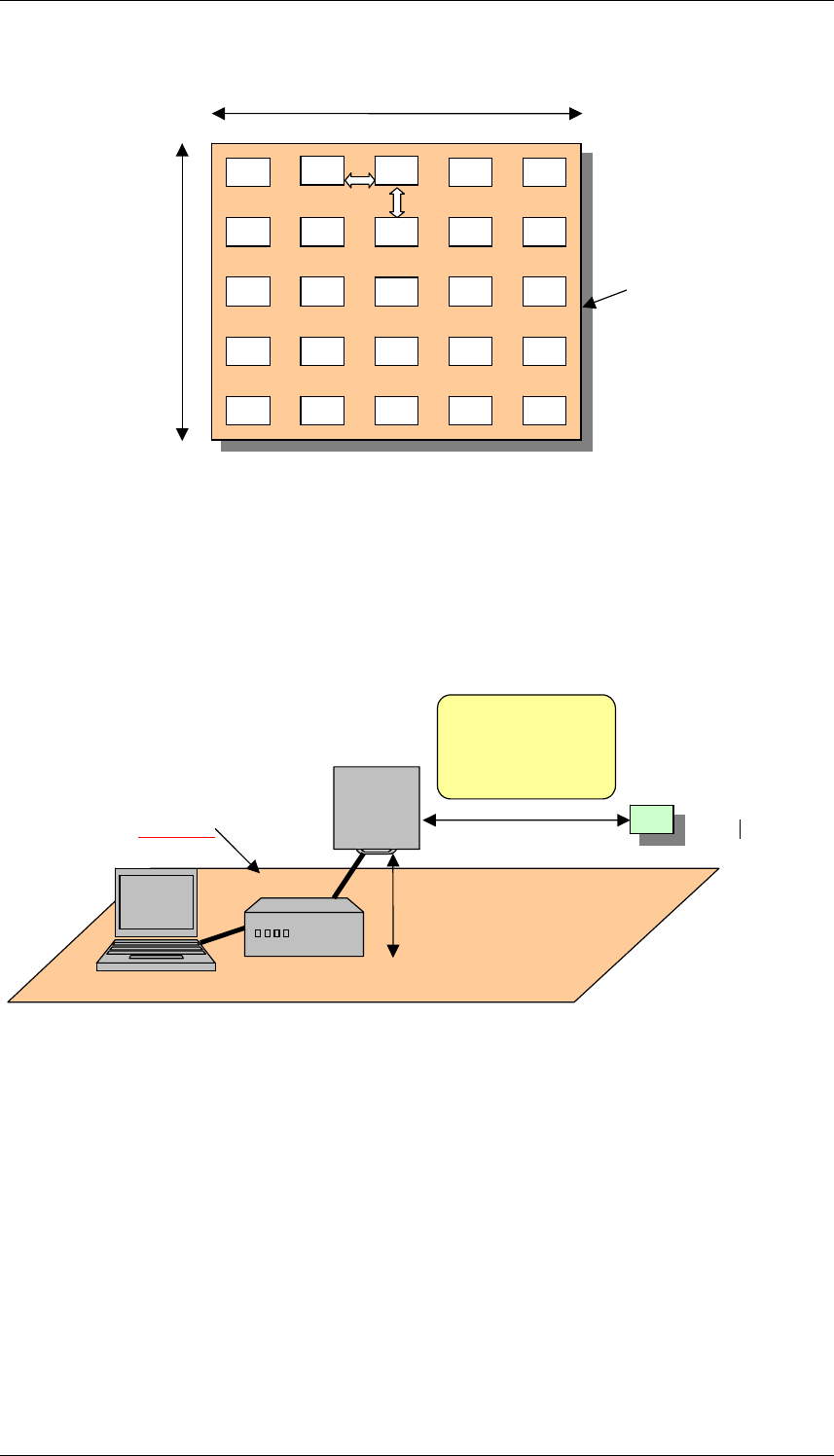

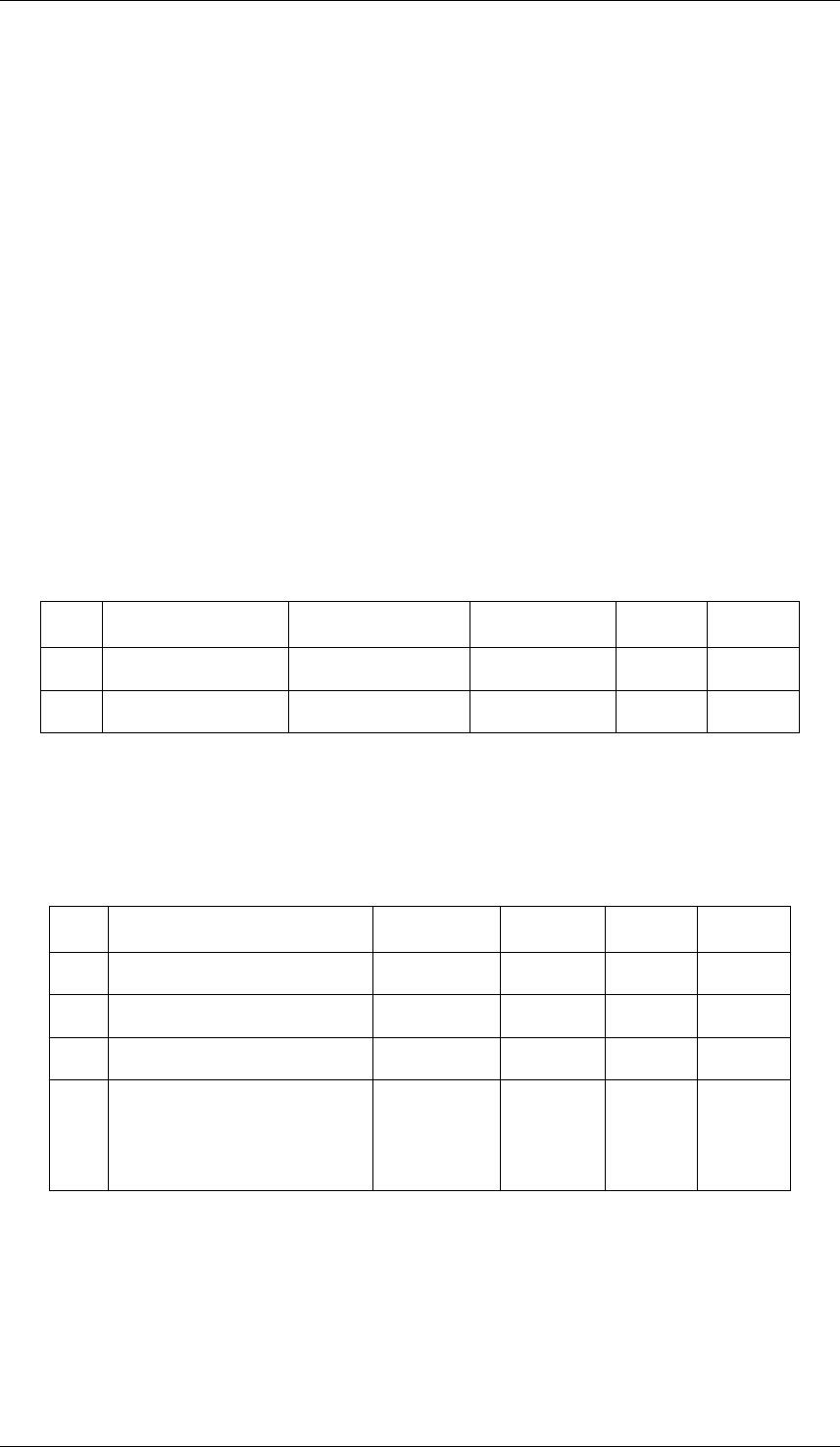

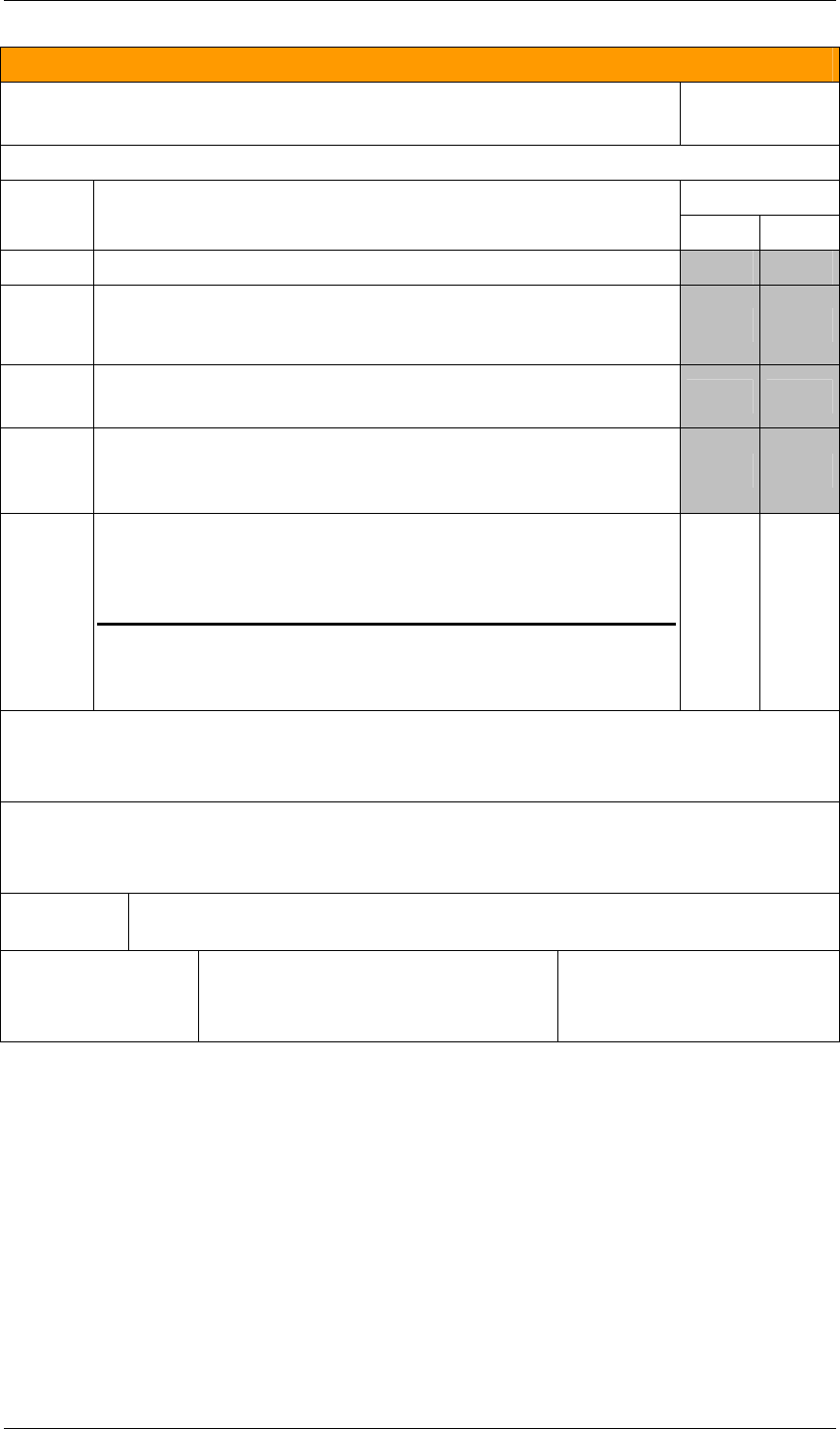

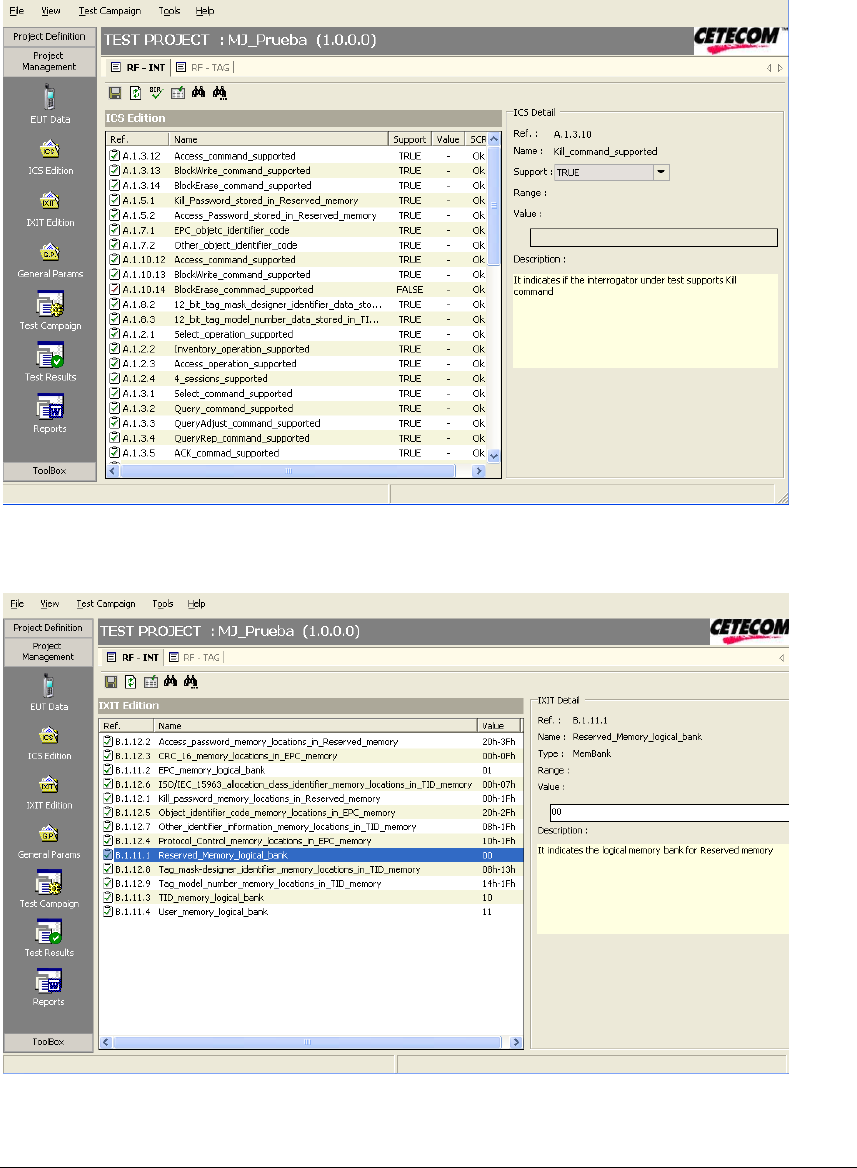

7.3 Test Sites for Interoperability

Test Site

3

Height of the

antenna

4

1

2

Suitable distance

between the

interrogator and

the tag

Flat

surface

1 Interrogator antenna

2 Interrogator

3 Tag

4 Host

Figure 2. Test Site 1

Description of the tag placement:

- The tag shall be at fixed and stationary position.

Date: 2006-08-04 Version 1.2.4 Page 35 of 84

Interoperability Test System for EPC compliant Class-1 Gen-2 UHF RFID

- The geometrical centre of the tag shall be aligned horizontally with the

geometrical centre of the interrogator antenna and the tag orientation facing the

antenna.

- Tag placement shall be on a non-conducting material, for example cardboard.

Tags should be placed facing the interrogator antenna.

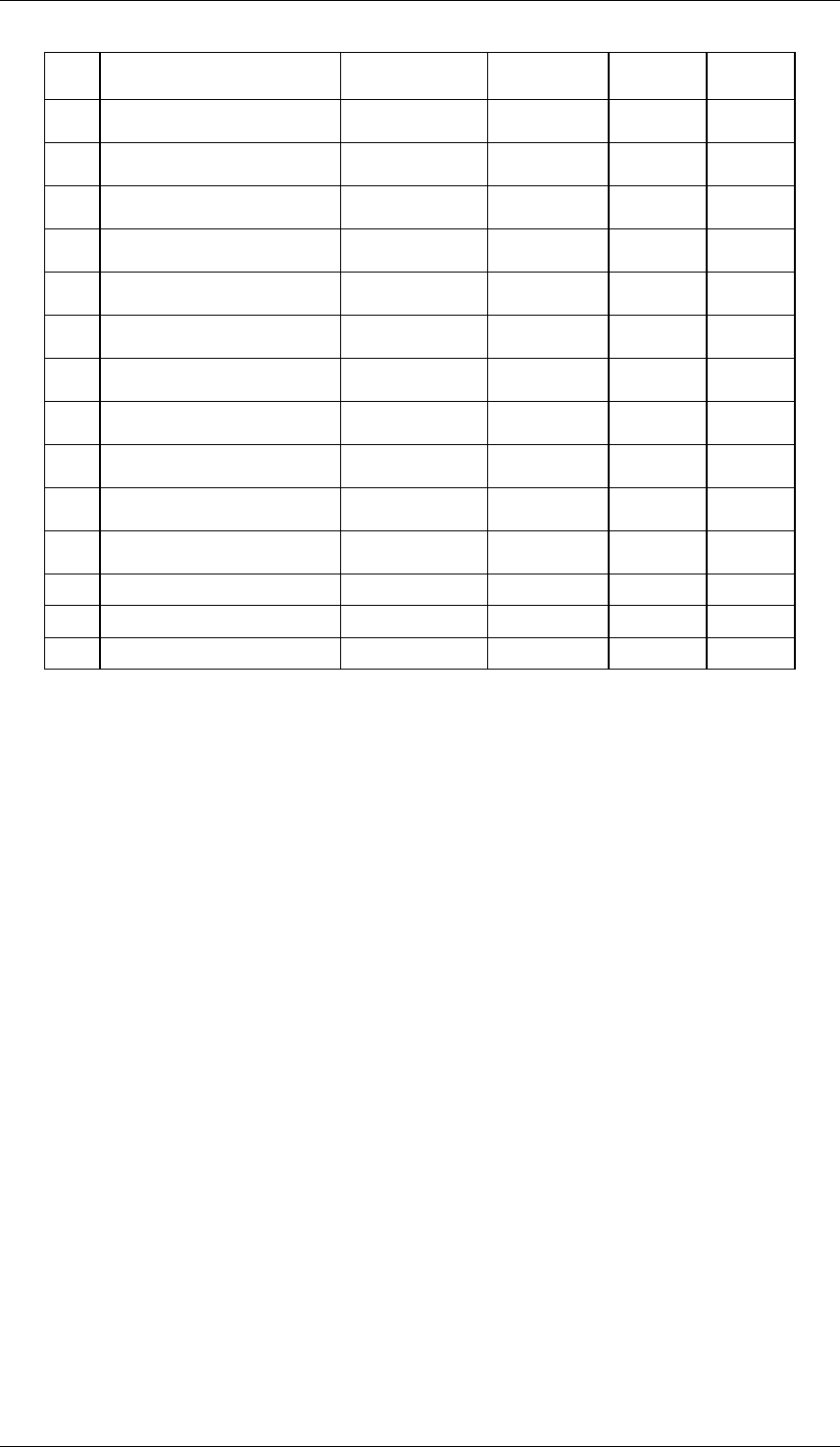

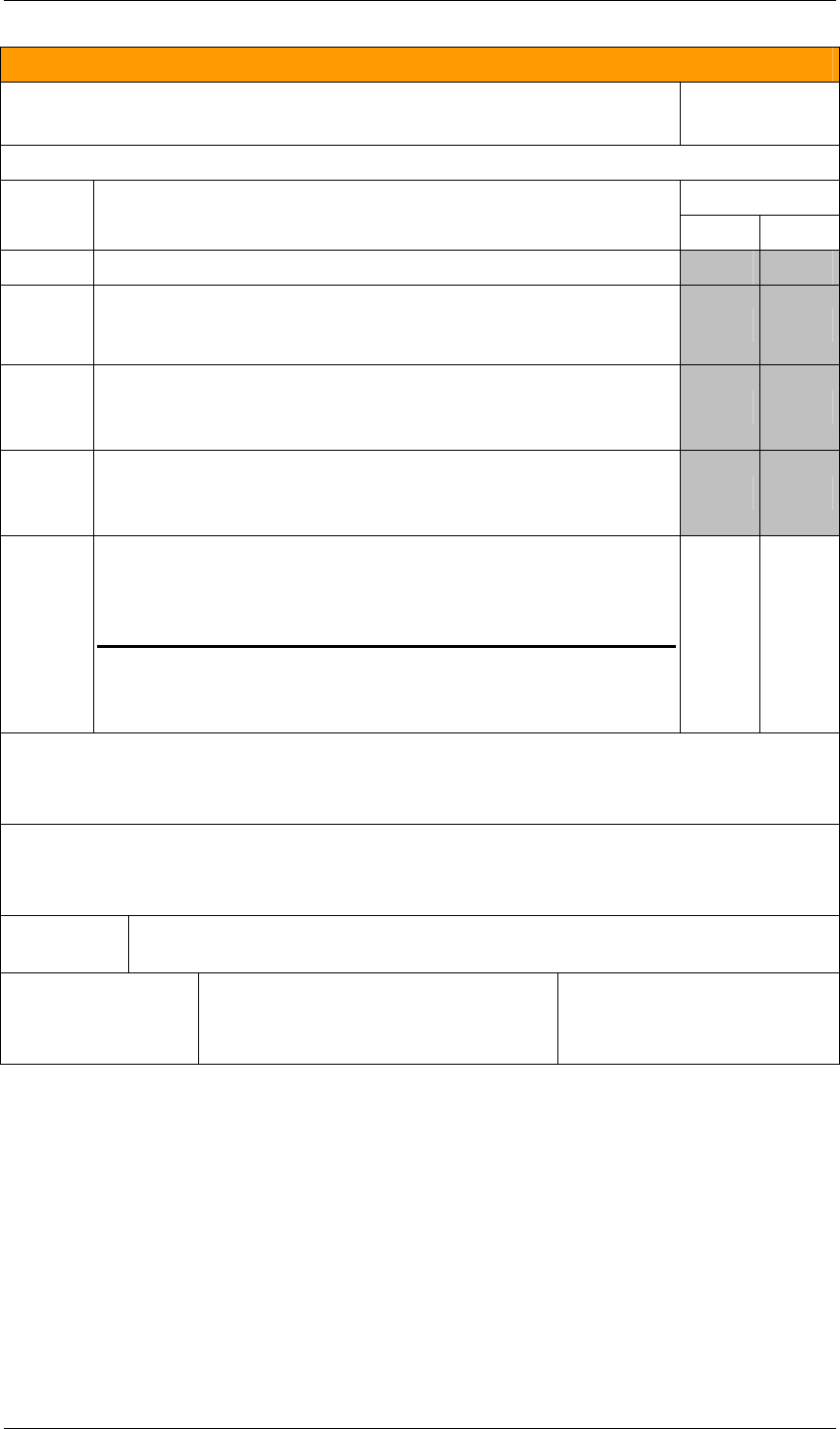

Test Sites 2 and 3

Height of the

antenna

4

1

2

3

Flat surface

Suitable distance

between the

interrogator and

-

tag

the multiple

setup

1 Interrogator antenna

2 Interrogator

3 Multiple-tag setup

4 Host

Figure 3. Test Sites 2 and 3

Description:

- The multiple-tag setup shall be at fixed and stationary position.

- The geometrical center of the multiple-tag setup shall be aligned horizontally with the

geometrical center of the interrogator antenna and its orientation facing the antenna.

- Test Site 2 shall consist of a population of tags from the same vendor. This is referred

to as a homogeneous multi-tag population.

- Test Site 3 shall consist of a population of tags from the different vendors. This is

referred to as a mixed multi-tag population.

Date: 2006-08-04 Version 1.2.4 Page 36 of 84

Interoperability Test System for EPC compliant Class-1 Gen-2 UHF RFID

Date: 2006-08-04 Version 1.2.4 Page 37 of 84

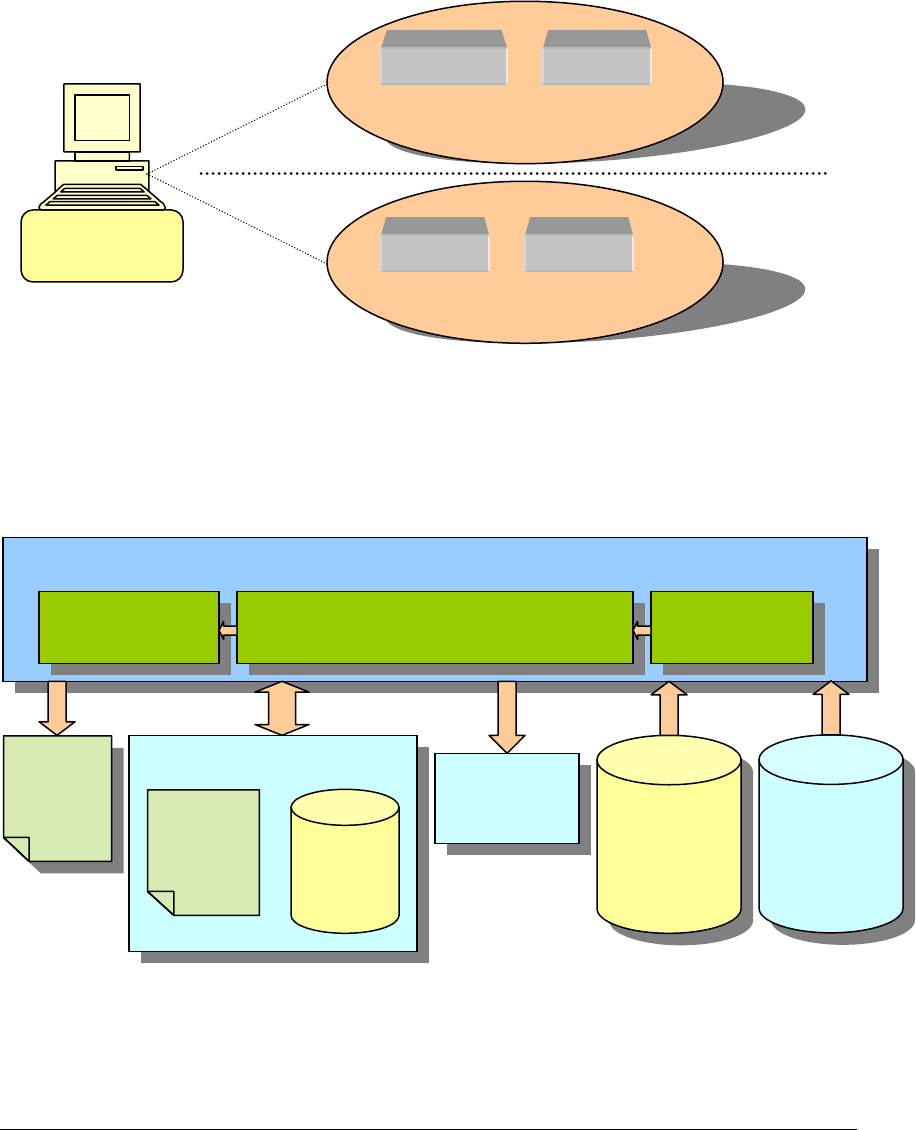

7.4 Qualified Equipment

In order to conduct interoperability tests a set of QE must be identified to used. QEs are

standard commercial products that have been selected for the purpose of interoperability testing

and shown to be fully compliant with reference standards.

When implementing the test cases the test operator can choose between two possible test

scenarios:

- Interrogator under test against tag under test. There is not qualified equipment in this

test scenario. Both, the interrogator and the tag are EUTs.

- EUT tested against qualified equipment. The qualified equipment will be an

interrogator, a tag or a multiple-tag set-up depending on the device submitted for

testing and the test purpose.

See Annex D for more information.

7.5 Test System Validation

The system validation will be carried out using an interrogator and a tag population with the

following characteristics:

- The selected interrogator and the tag population shall belong to the same

manufacturer, in order to assure proper communication between them.

- Both the interrogator and tag population shall have successfully passed the RF and

Protocol conformance tests.

Each interoperability test case will be validated running it with the described devices and until a

complete test campaign is completed. This can be accomplished by single stepping through each

test case or by exercising a group of Script Files that accomplish the same task.

INTEROP-RFID IS PROFORMA RFID INTEROP TEST SYSTEM ANNEX A

ANNEX A

IS and IXIT specification

A.1 Scope

The present document provides the Implementation Statement (IS) proforma for the radio-

frequency identification (RFID) system operating in the 860 MHz – 960 MHz frequency range

defined in EPCglobal Class-1 Generation-2 UHF RFID Protocol V.1.0.9 in compliance with the

relevant requirements, and in accordance with the relevant guidance given in ISO/IEC9646.

A.2 References

[1] EPCglobal Class-1 Generation-2 UHF RFID Protocol V.1.0.9

[2] ISO/IEC 9646-1: "Information technology - Open systems interconnection -

Conformance testing methodology and framework – Part 1: General concepts".

[3] ISO/IEC 9646-7: "Information technology - Open systems interconnection -

Conformance testing methodology and framework – Part 7: Implementation

Conformance Statements".

[4] ETSI TS 102 237-1 v 4.1.1 (2003-12): Telecommunications and Internet Protocol

Harmonization Over Networks (TIPHON) Release 4; Interoperability test methods

and approaches; Part 1: Generic approach to interoperability testing.

A.3 Definitions

In particular, the following terms and definitions apply:

Interoperability Statement (IS): It is a checklist of the capabilities/functionalities supported

by the Equipment Under Test. IS is used to select and parameterize test cases and as an indicator

for basic interoperability between different products.

IS proforma: A document, in the form of a questionnaire, which when completed for an

implementation or system becomes an IS.

Implementation eXtra Information for Testing (IXIT): It contains additional information

(e.g., specific addresses, timer values, etc.) necessary for testing.

A.4 Abbreviations

IS Implementation Statement

IUT Implementation Under Test

SUT System Under Test

A.5 Conformance to this IS proforma specification