BUILDER PROFILE

Builder: Tommy Williams Homes

Gainesville, FL

www.tommywilliamshomes.com

Founded: 1978

Employees: 11

Development: Belmont (136 homes)

and Longleaf Village (275 homes)

1,470 to 3,045 ft

$190,000 to $370,000

Construction Date: 2007-2011

“The market has spoken. Energy efciency sells,” said Todd Louis,

vice-president of Tommy Williams Homes in Gainesville, Florida. Since

partnering with the U.S. Department of Energy’s Building America

program in 2004, Tommy Williams’ production homes have outsold

the competition, with sales increasing year after year in spite of the

recession. The key, Louis said, is the systems-engineering approach that

produces high levels of energy efciency, comfort, and indoor air quality.

The company is so condent in its homes’ energy savings that it offers to

pay the buyer’s energy bill for the rst year.

In 2010 Tommy Williams built 36 homes, and every one has a Home

Energy Rating System (HERS) score under 60. By comparison, a home

built to minimum Florida code will have a HERS score as high as 85.

The company’s expertise was developed in partnership with Florida

HERO, an energy consulting rm, and other members of the Building

America Industrialized Housing Partnership. The team provided

systems engineering support, energy simulations with cost data, and

hands-on construction education.

“Building high-performance homes is not expensive,” said Florida

HERO president Ken Fonorow. “In fact, these methods are so cost-

effective that there’s absolutely no reason for a builder to build a less

energy-efcient home.”

Energy-Efficiency Features

Tommy Williams’ homes are in the Longleaf Village and Belmont

developments in the hot-humid climate of Gainesville, Florida. The

one- and two-story homes have three to ve bedrooms, range from

1,470 to 3,045 ft², and sell for $190,000 to $370,000.

BUILDING TECHNOLOGIES PROGRAM

Tommy Williams Homes, a production builder

in Gainesville, Florida, built 36 homes in 2010,

all of which achieved HERS scores under 60.

The Building America Industrialized Housing

Partnership has worked with Tommy Williams

Homes since 2004 to meet the company’s

goal of building high-performance, energy-

ecient homes.

Building America Best Practices Series

Volume 15. Builders Challenge Guide to 40% Whole-House

Energy Savings in the Hot-Humid Climate

Case Study:

Tommy Williams Homes

Gainesville, FL

R

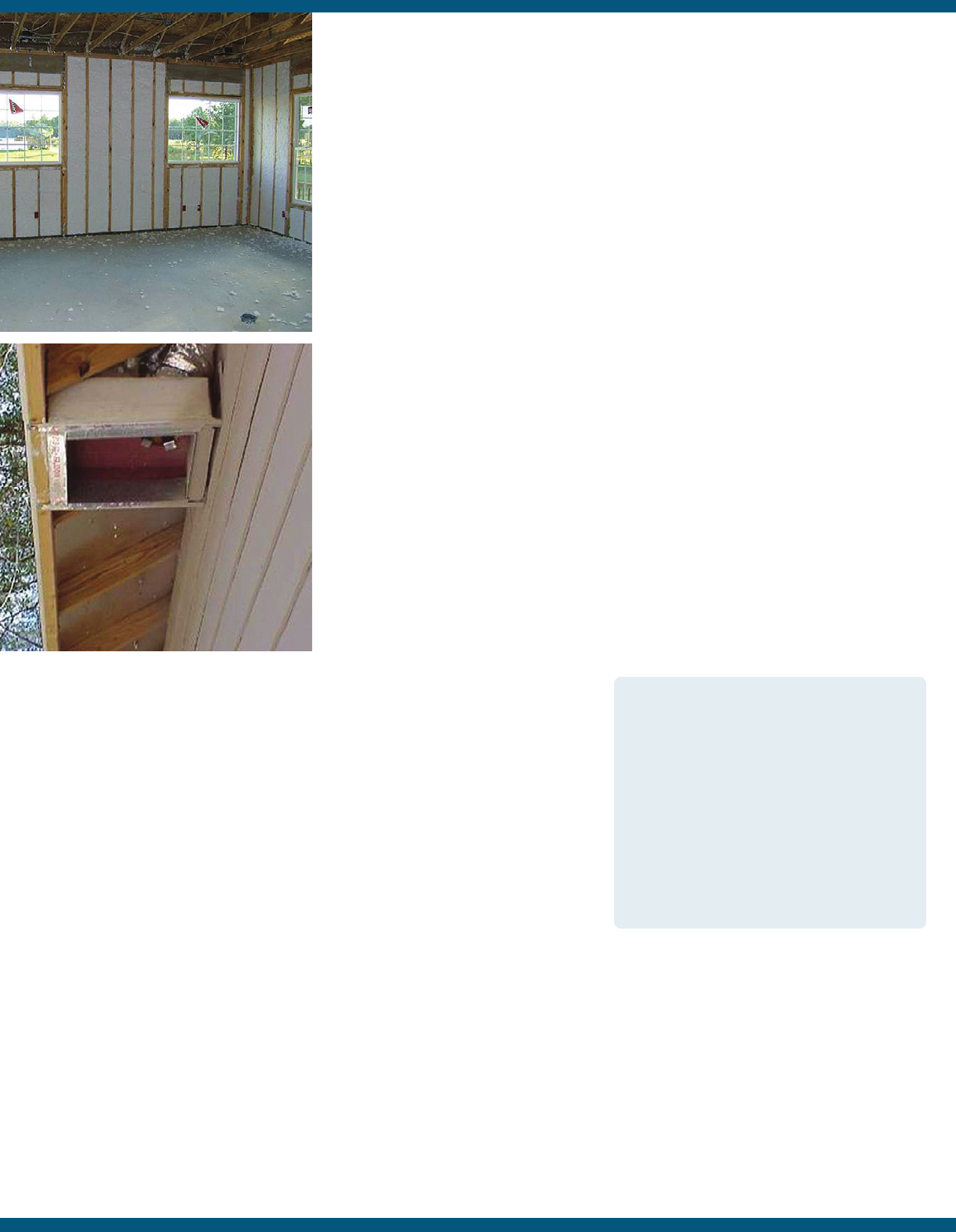

The tight thermal envelope in Tommy Williams’ homes is achieved with

walls and attics that are sealed and insulated. Wall cavities of the 2x4

16-inch on-center framed walls are lled with R-15, formaldehyde-free,

blown berglass insulation. Ladder T framing creates extra room

for insulation. A foam gasket is used to seal the air gap between the

drywall and top plate of the walls. Holes around pipes and wiring in

the exterior walls are sealed with expanding foam. The vented attic has

R-30 blown-in insulation with kneewall air barriers, foam gaskets, and a

radiant barrier on the underside of the roof decking. Blower-door tests

show 2.7 air changes per hour at 50 Pascals.

Because a hot, humid climate can pose air quality problems, the HVAC

system must be carefully designed. Since air conditioning removes

humidity in summertime, the air conditioner must be sized correctly for

the home, said Fonorow of Florida HERO. An overly large system will

cool the home and cycle off too quickly, allowing humidity to build up.

Tommy Williams Homes used ACCA Manual J to size the SEER 16,

HSPF 9.5 heat pump with a MERV 8 air lter.

In the wintertime, humidity problems are caused by internally generated

moisture from cooking and bathing. The problem is solved in Tommy

Willams’ homes with a positive pressure ventilation system in which

drier outdoor air is drawn to the return side of the air handler,

downstream from the return air lter. The system supplies fresh air only

when the air handler is running. When fresh air is introduced, Fonorow

said, the positive pressure in the house pushes stale air out of the home.

For additional humidity control, bathroom fans are equipped with a

moisture sensor. The fans

run automatically, venting

moist air to the outside, until

the humidity is reduced to a

set point.

Louis said the positive

pressure ventilation system

has been used successfully

for more than a decade,

but too few builders take

advantage of it.

The houses’ ducts, sized according to ACCA Manual D, are sealed

with mastic at joints and located in the attic. The attic’s radiant barrier

protects the cool air in the ducts from heat gain in the hot, humid

climate. Duct tests show 4% air leakage at 25 Pascals. Tommy Williams

is working on designs that move the ducts into conditioned space.

Tommy Williams uses covered porches to protect the large window

areas from solar heat gain. The low-emissivity vinyl-framed windows

are U=0.35, SHGC=0.25. Energy savings also come from a tankless gas

water heater that is 0.83 EF.

(Top) Tommy Williams Homes uses

formaldehyde-free blown fiberglass

insulation for R-15 in the walls and R-30

in the attics.

(Bottom) Fresh air intakes are installed in

the roof sot or porch ceiling and ducted

to the air handler’s return plenum to bring

filtered fresh air to the house.

“There isn’t a person in the

country who is not interested

in having a lower energy bill.

It costs less to spend a few

thousand dollars up front and

have a lower utility bill for the

life of the home.”

TODD LOUIS

Vice-President, Tommy Williams Homes

BUILDING AMERICA BEST PRACTICES SERIES

2

Building America partner Florida HERO conducts midpoint and nal

inspections on every home built by Tommy Williams. In addition to duct

leakage and blower door tests, the independent consultant conducts

the ENERGY STAR thermal bypass inspection and pressure mapping.

Florida HERO also measures the mechanical ventilation ow, the supply

air ow, the HVAC system static pressure, and temperature differences

across the HVAC coil exhaust.

Health, Durability, Sustainability

All of Tommy Williams’ homes meet or exceed the standards for

ENERGY STAR certication and certication by the Florida Green

Building Coalition. The builder uses zero-VOC paint. The duct board is

anti-microbial. Moisture-resistant brick and ber-cement siding add to

the homes’ durability.

Innovation

“The most important innovation we use is taking a whole house

approach,” Louis said. “We’re not just giving customers a few energy-

efcient options to choose from like low-e windows, the radiant barrier,

the interior duct system, or advanced framing techniques. We’re putting

them all together to create a much better home.”

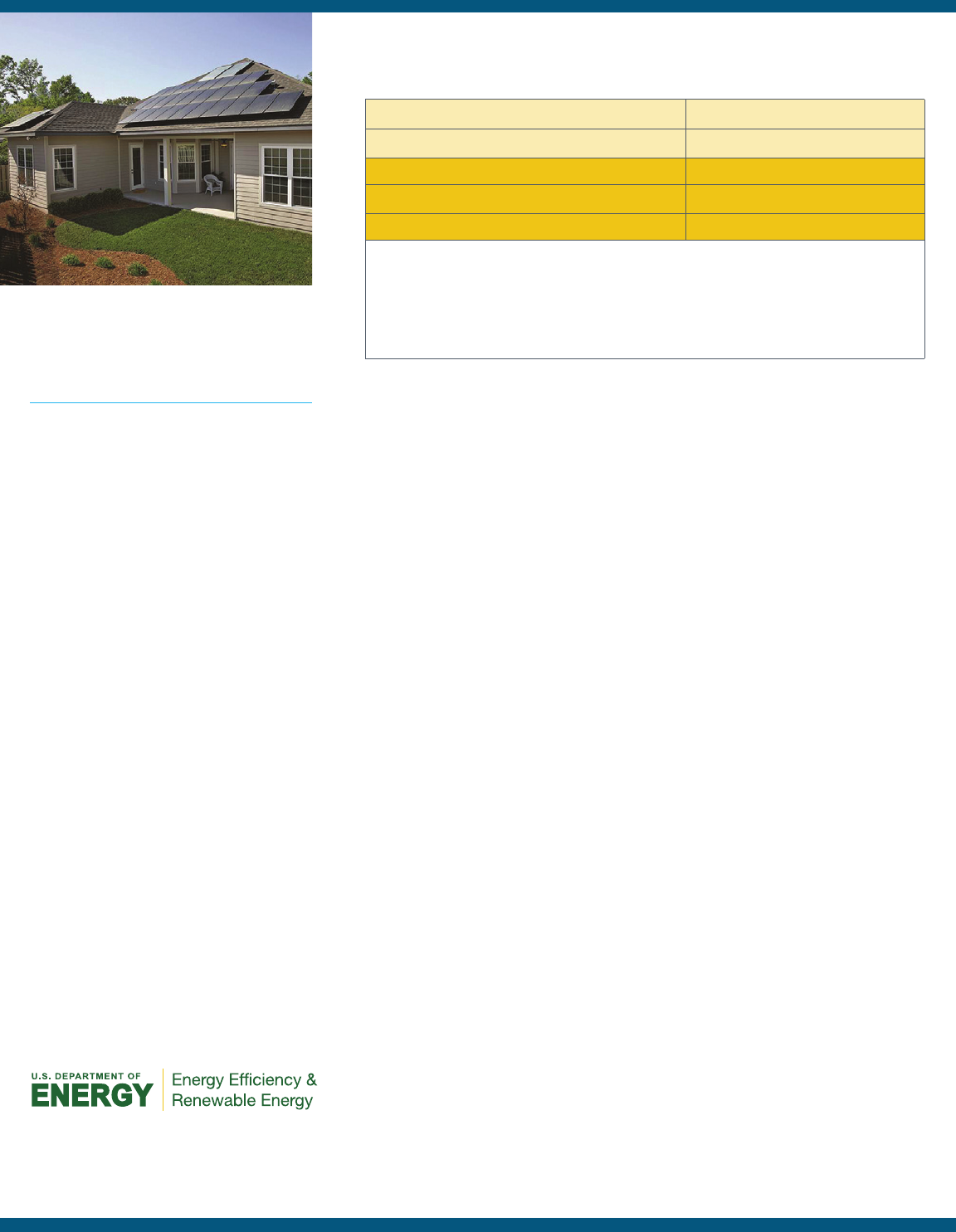

The company’s innovations don’t stop there. Tommy Williams has worked

with the Building America team BAIHP to build two net-zero-energy

homes with photovoltaic panels and solar hot water systems. The homes

have a HERS score of -2, which means they produce more energy than

they consume. The company is constructing a third zero-energy home

and has developed a set of net-zero-energy “ready made” home plans.

“These homes are becoming more affordable,” Louis said. He expects

to see “a tipping point coming very soon where we’ll be selling more

zero-energy homes than standard homes. It’s just the right thing to do

for our kids and grandkids.”

Dollars and Sense

The energy-efcient features of a Tommy Williams home increase its

cost, on average, by about $3,300, compared to a similar home built to

minimum Florida code. When nanced as part of a 30-year mortgage,

this means a cost to the homeowner of about $265 a year. But the

reduction in energy bills averages $930 a year. The buyer wins.

To underscore how low the home’s energy bill will be, Tommy Williams

Homes offers to pay it for the rst year. “This is more than a sales

incentive,” said Louis. “It tells customers that we stand behind our

energy-efcient features.”

Energy-Efficient Features

• HERSscores:48-58

• Foundation:Slab-on-grade

• Siding:Brickandbercement

• Wallinsulation:R-15,formaldehyde-

free, blown fiberglass

• Attic:Radiantbarrier,R-30blown-in

insulation, kneewall air barriers, foam

gasket sealing

• HVAC:ACCAManualJsizing,

variable speed air handler, SEER 16,

HSPF 9.5 heat pump

• Ventilation:Fresh-air,intaketothe

returnsideoftheairhandler,MERV8

air filter, moisture-sensor-controlled

exhaust fans

• Ductsystem:ACCAManualDsized,

anti-microbial duct board, mastic

sealed

• Waterheating:Tanklessgas,0.83EF

• Windows:Low-E,double-pane

insulated vinyl windows, U=0.35,

SHGC=0.25

• Lighting:100%CFL

• Appliances:ENERGYSTAR

dishwasher

3

CASE STUDY: TOMMY WILLIAMS HOMES

Table 1. Calculated Costs and Savings of Energy-Efficiency

Features for Tommy Williams Homes, Gainesville, Florida

Total Energy Savings vs. Benchmark

1

42%

TotalAddedBuilderCost

2

$3,314

Annual Utility Bill savings $930

AnnualMortgagePaymentIncrease

2, 3

$265

AnnualNetCashFlowtotheHomeowner $665

1

Savings are in comparison to the Building America benchmark (a home built to the 1993 Model

Energy Code)

2

Builder costs were estimated by builders and Building America team. Costs include a 10%

markup. Incentives and rebates are not included.

3

Mortgage costs are based on a 30-yr fixed mortgage at 7% interest; inflation is not considered.

The Bottom Line

Tommy Williams Homes has proven to buyers that they can save

money and have a better home, Louis said. Sales gures conrm this.

In Longleaf Village, Tommy Williams and a competitor each own half

of the 550 lots. But Tommy Williams’ houses are selling faster. In 2010,

Tommy Williams sold 23 homes in the development, the competitor just

16, even though the energy-efciency features of a Tommy Williams

house mean a higher price per square foot – $139.13 compared to the

competitor’s $126.34. Clearly, customers are willing to pay extra for the

benets of a high-performance, energy-efcient home.

For Fonorow, what’s most exciting is that Tommy Williams Homes

demonstrates unequivocally that companies can build production homes

with HERS scores in the 50s and utility bills under $100 a month using

off-the-shelf products, installed by standard contractors. “And Tommy

Williams Homes has reaped the rewards of increased sales and quicker

turnaround times,” said Fonorow.

For More Information

www.buildingamerica.gov

EERE Information Center

1-877-EERE-INF (1-877-337-3463)

eere.energy.gov/informationcenter

PNNL-SA-78346 September 2011

Tommy Williams Homes’ first zero energy

homewascompletedinJanuary2010

and had a tested HERS score of -2.

Tommy Williams Homes’

Recipe for High-Performance

Homes in a Hot-Humid Climate

• Createatightthermalenvelope.

• Installapositivepressure

ventilation system.

• Right-sizetheHVACequipment

and duct system.

• Placetheairhandlerin

conditioned space.

• Designthehousewithpassive

strategies to reduce solar heat gain.

• Installlow-emissivitywindows.

• Employindependenttestingfor

qualityassurance.

BUILDING AMERICA BEST PRACTICES SERIES

4